Primary funding is provided by The SPE Foundation through member donations and презентация

Содержание

- 3. Outline Waterflood design life and injection efficiency Conformance management Injection well

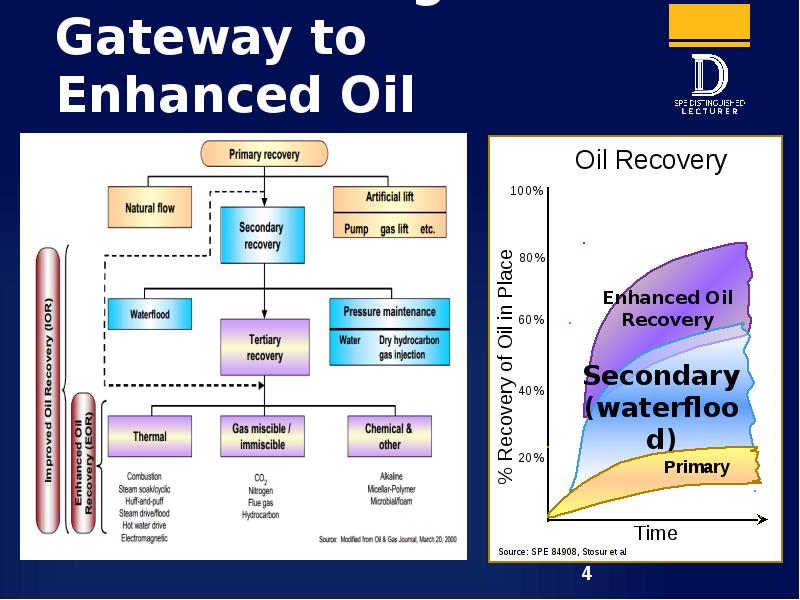

- 4. Waterflooding: The Gateway to Enhanced Oil Recovery

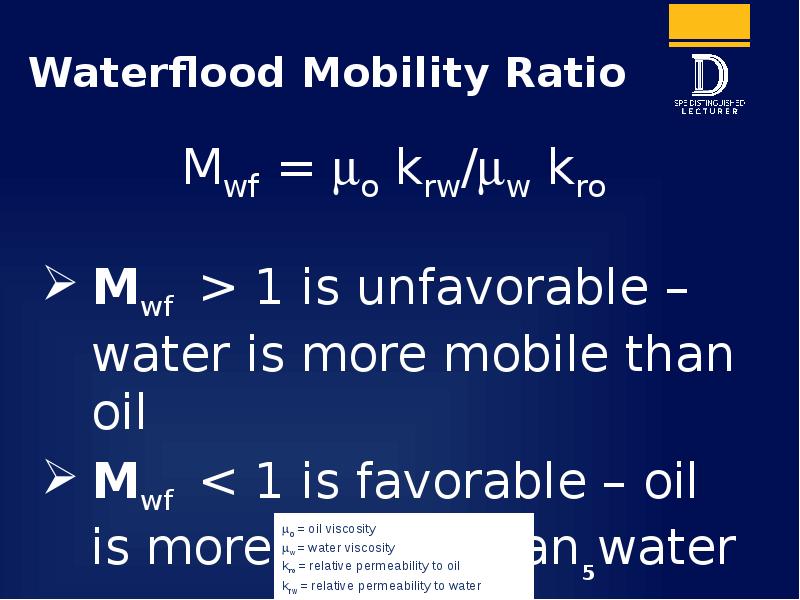

- 5. Waterflood Mobility Ratio Mwf = mo krw/mw kro Mwf > 1

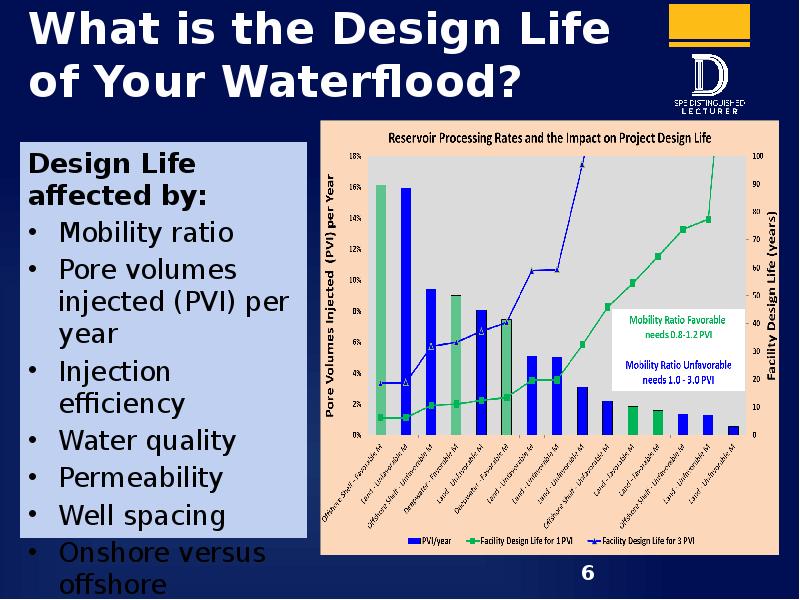

- 6. What is the Design Life of Your Waterflood? Design Life affected

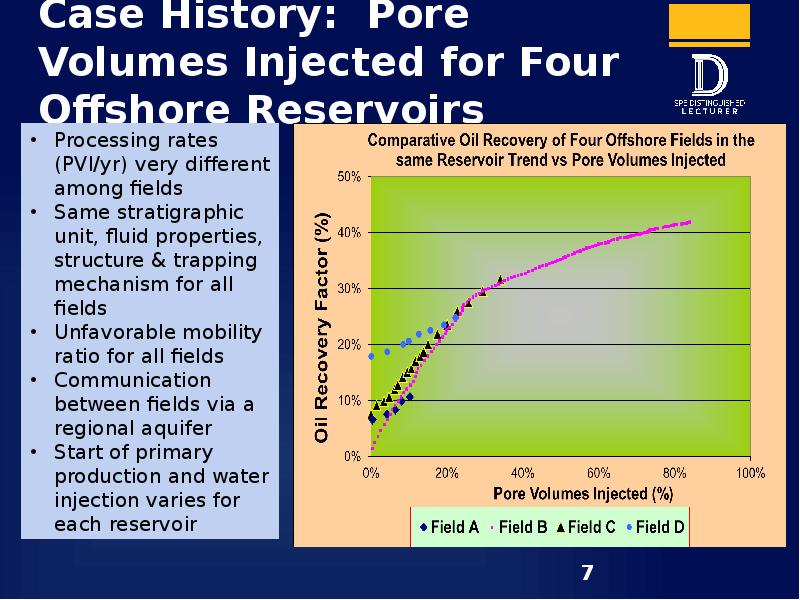

- 7. Case History: Pore Volumes Injected for Four Offshore Reservoirs

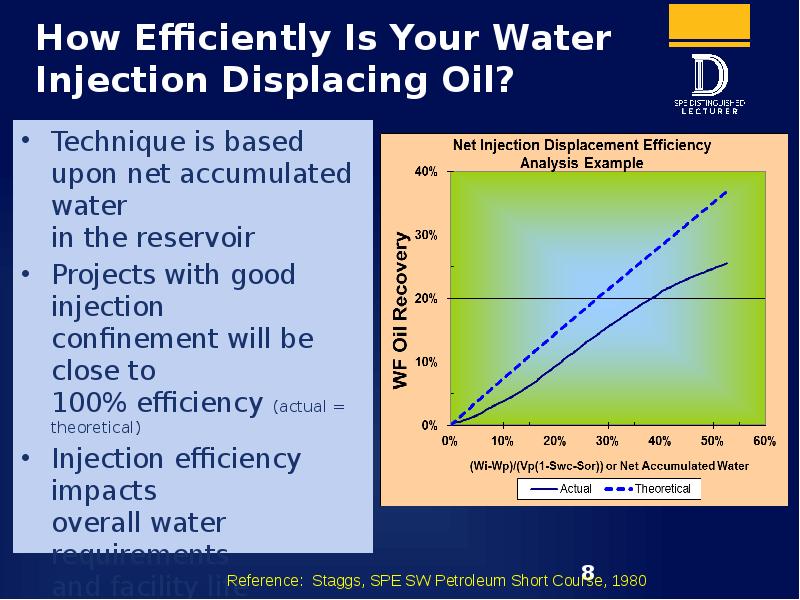

- 8. How Efficiently Is Your Water Injection Displacing Oil? Technique is based

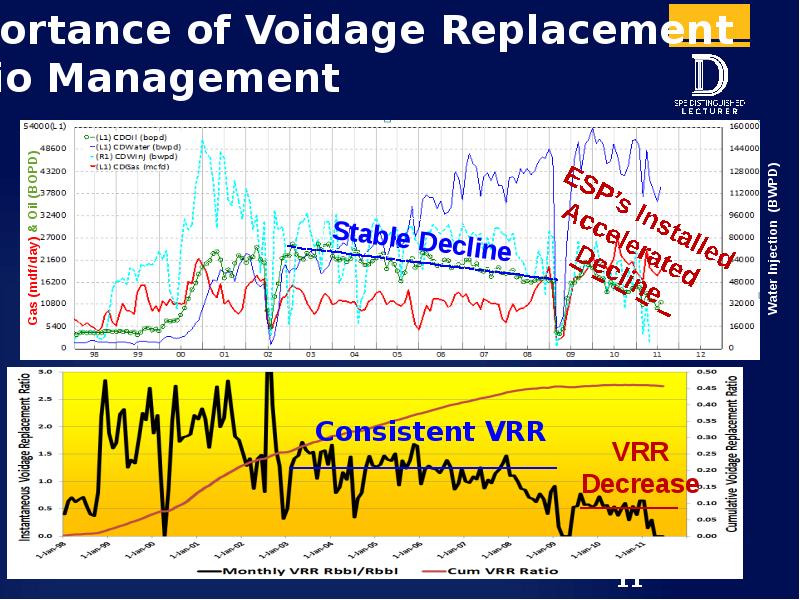

- 9. Voidage Replacement Ratio (VRR) VRR is used as a leading indicator

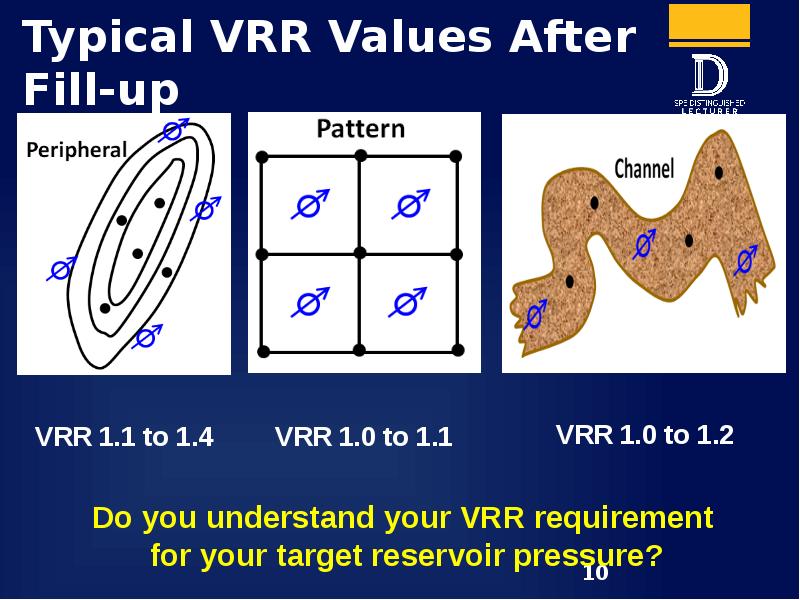

- 10. Typical VRR Values After Fill-up

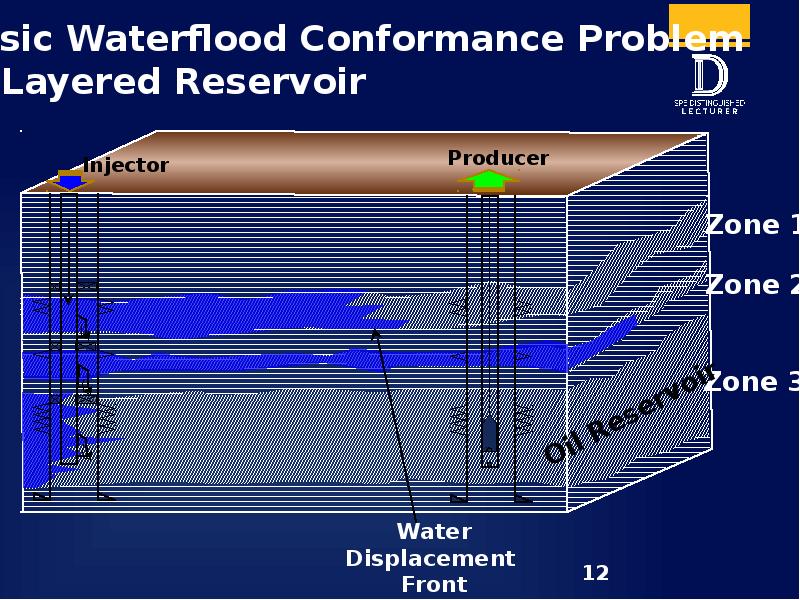

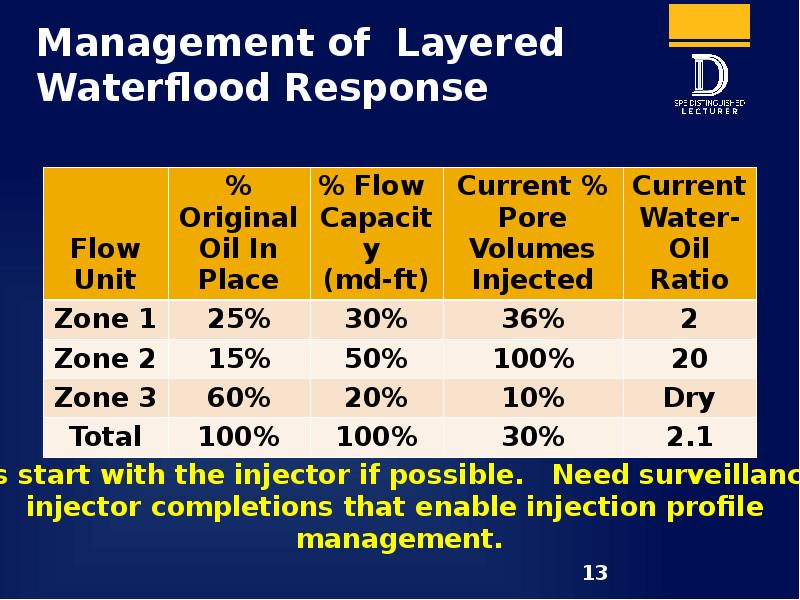

- 13. Management of Layered Waterflood Response

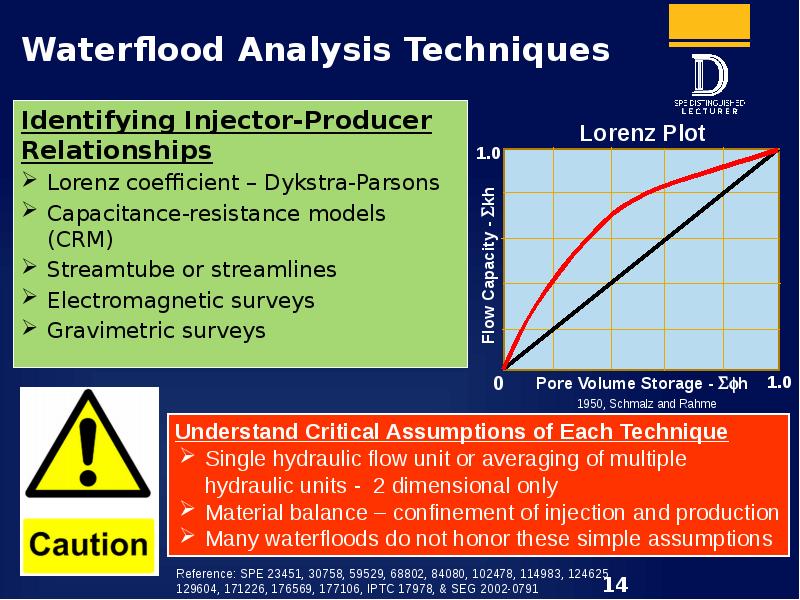

- 14. Waterflood Analysis Techniques Identifying Injector-Producer Relationships Lorenz coefficient – Dykstra-Parsons Capacitance-resistance

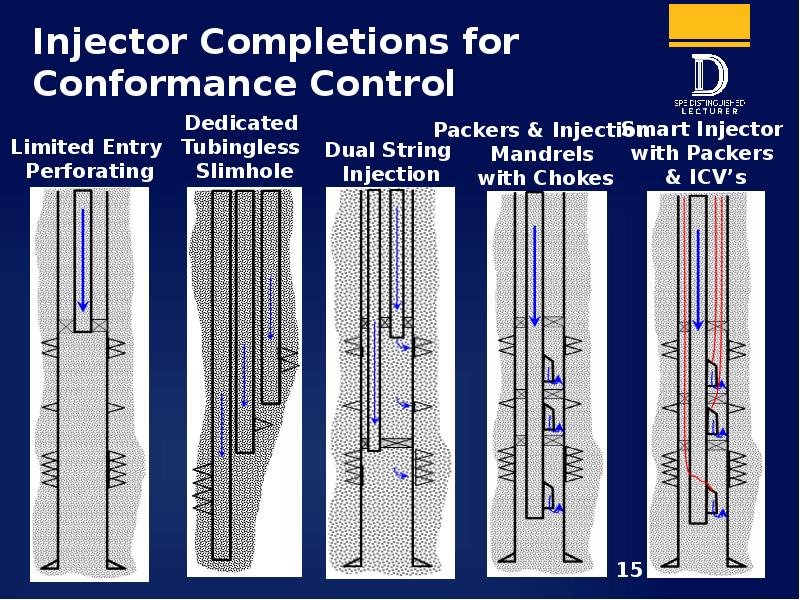

- 15. Injector Completions for Conformance Control

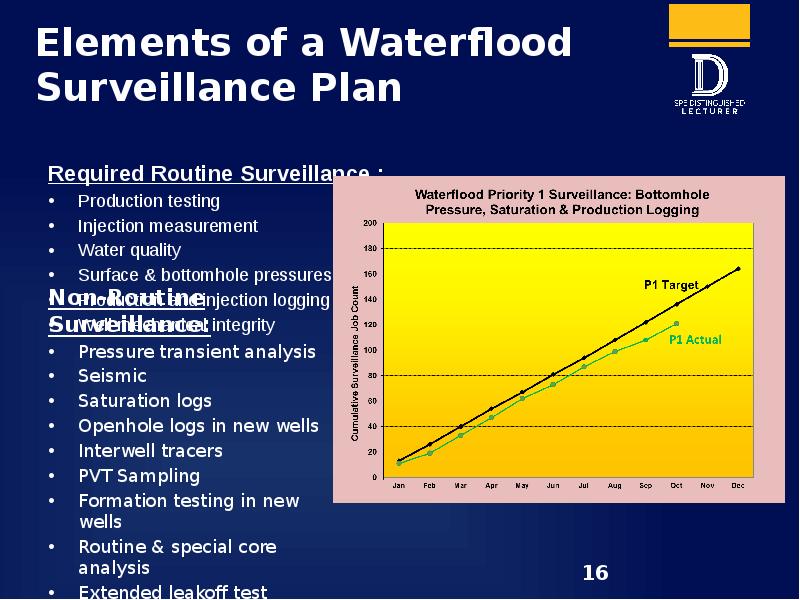

- 16. Elements of a Waterflood Surveillance Plan Required Routine Surveillance : Production

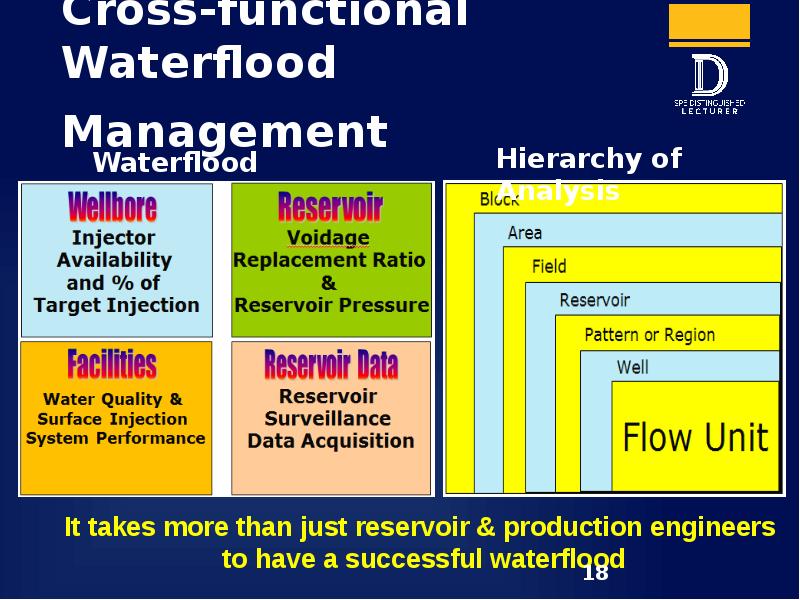

- 18. Cross-functional Waterflood Management

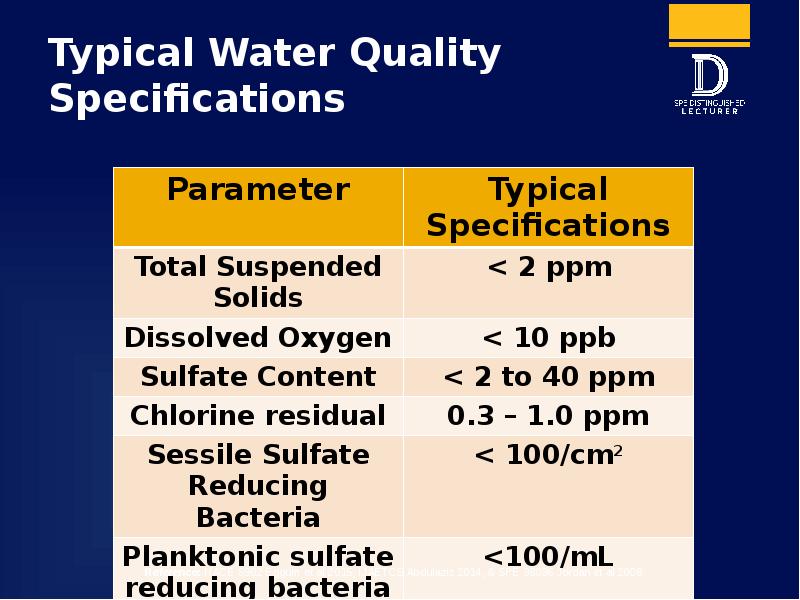

- 19. Typical Water Quality Specifications

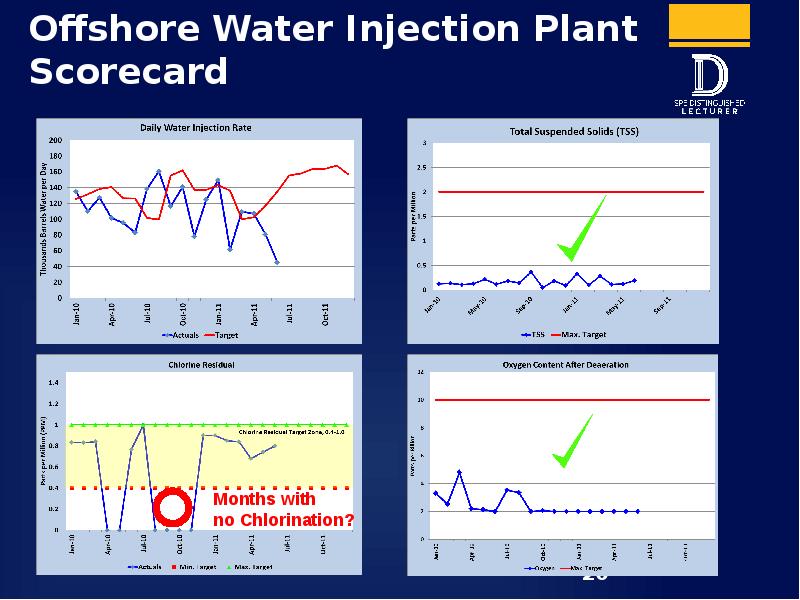

- 20. Offshore Water Injection Plant Scorecard

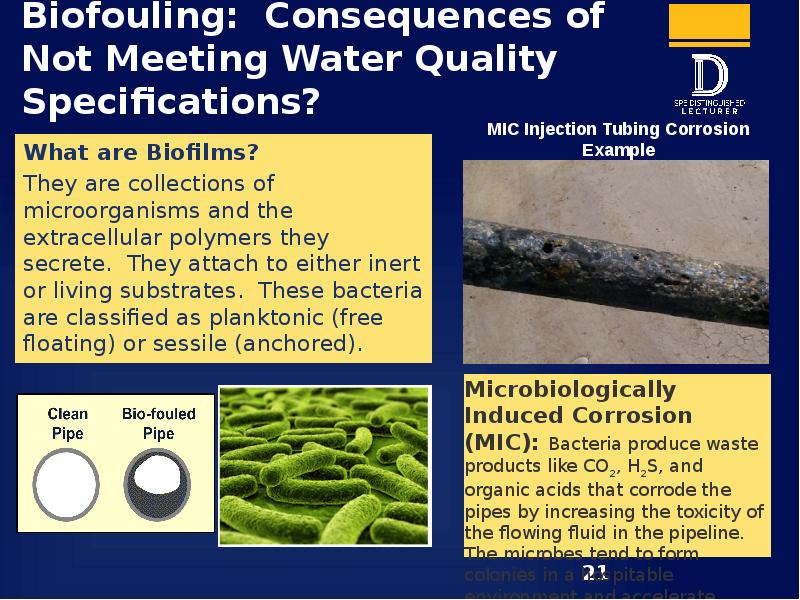

- 21. Biofouling: Consequences of Not Meeting Water Quality Specifications? What are Biofilms?

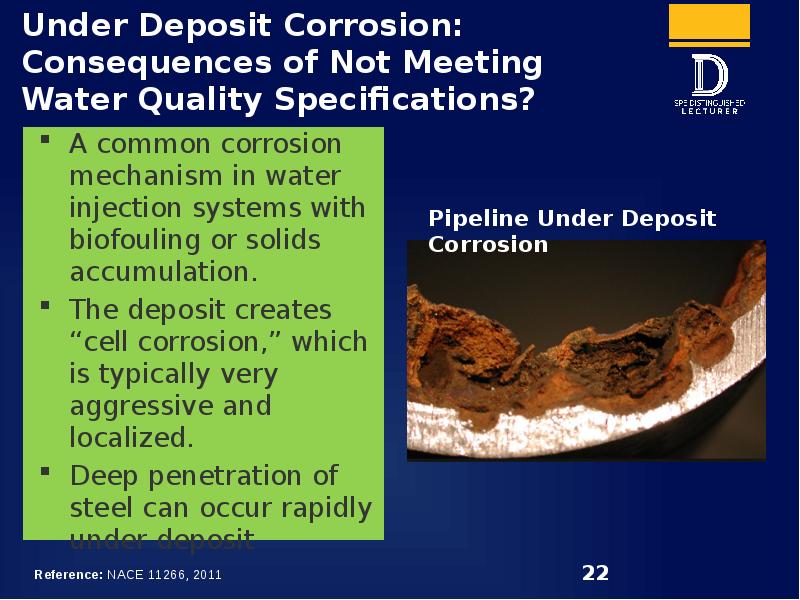

- 22. Under Deposit Corrosion: Consequences of Not Meeting Water Quality Specifications?

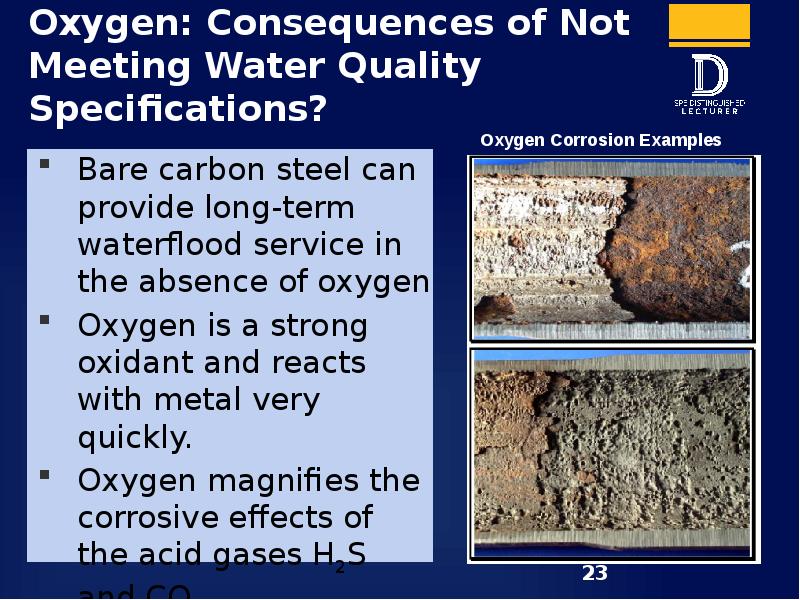

- 23. Oxygen: Consequences of Not Meeting Water Quality Specifications?

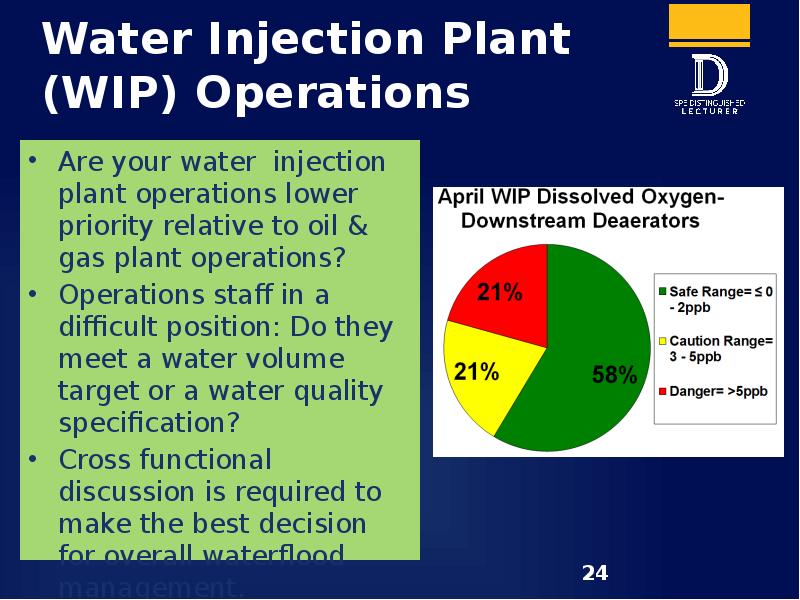

- 24. Water Injection Plant (WIP) Operations Are your water injection plant operations

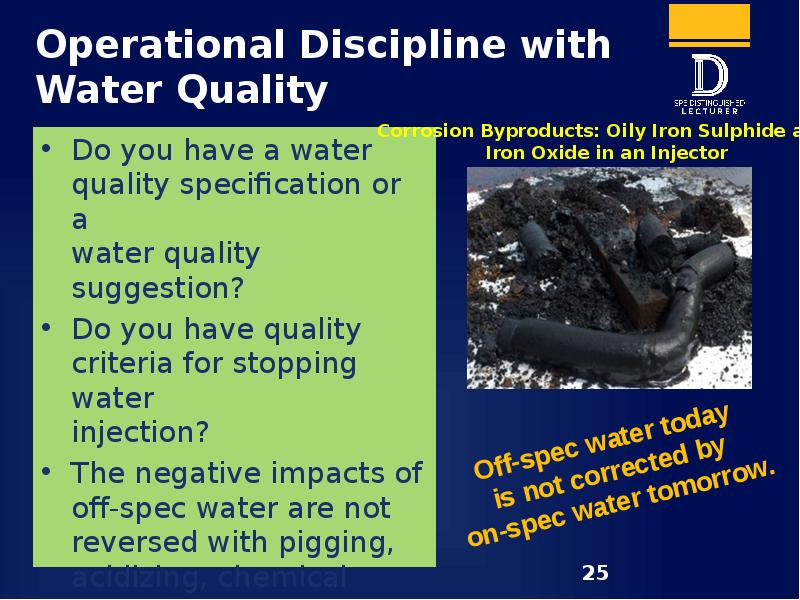

- 25. Operational Discipline with Water Quality Do you have a water quality

- 26. Matrix Injection Myth in Waterfloods Long term matrix injection cannot be

- 27. Subsurface Integrity Management for Waterfloods Subsurface integrity management ensures injected fluids

- 28. Key Takeaways Understand the design life and processing rate of your

- 30. Скачать презентацию

Слайды и текст этой презентации

Скачать презентацию на тему Primary funding is provided by

The SPE Foundation through member donations

and можно ниже:

Похожие презентации