Drilling Engineering презентация

Содержание

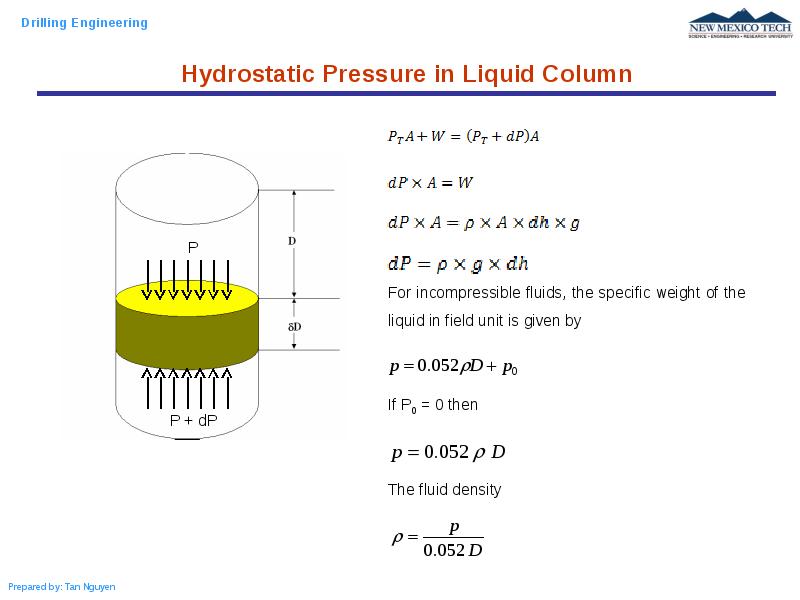

- 3. For incompressible fluids, the specific weight of the liquid in field

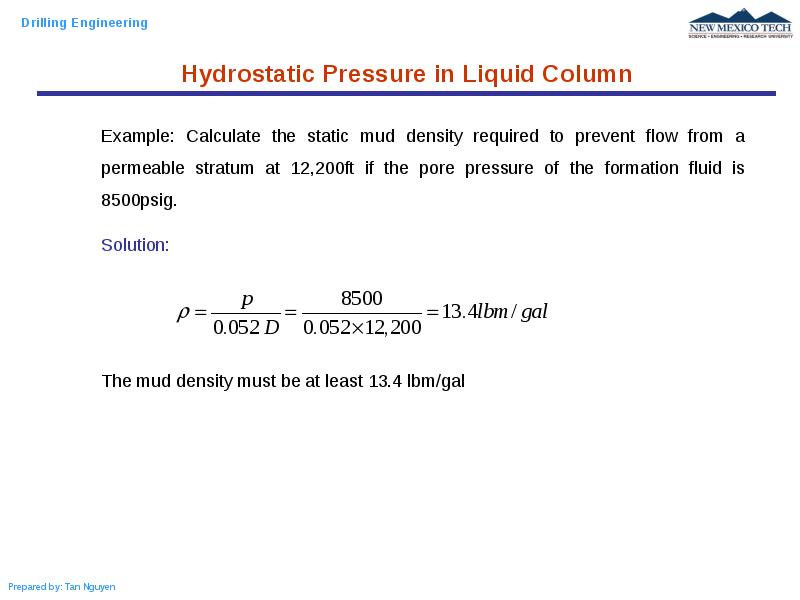

- 4. Example: Calculate the static mud density required to prevent flow from

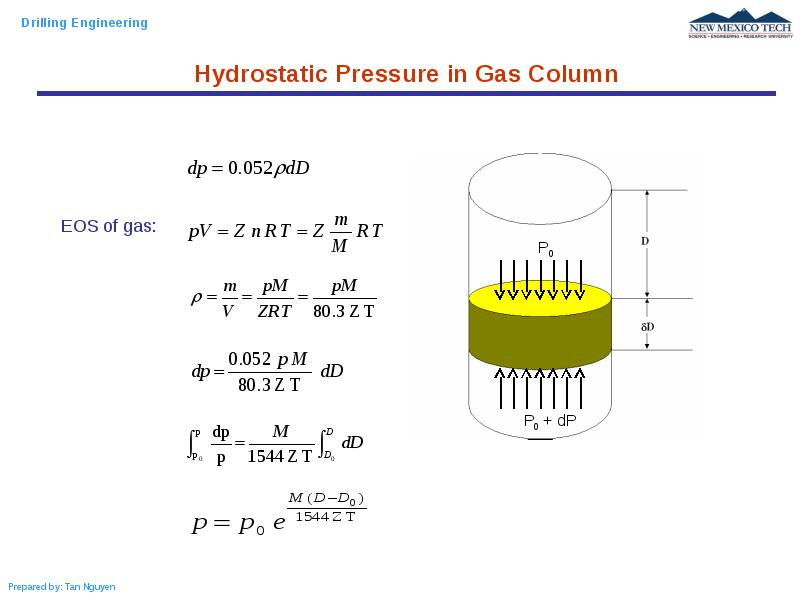

- 5. EOS of gas:

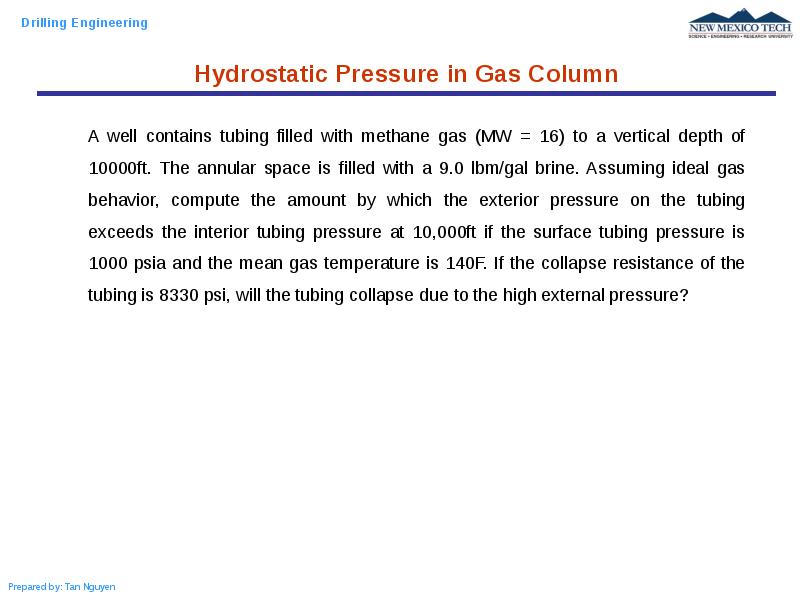

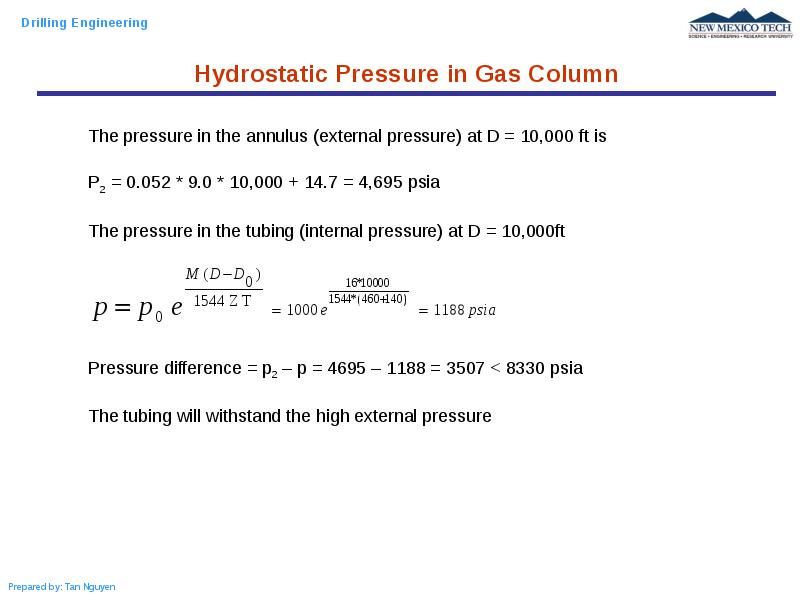

- 6. A well contains tubing filled with methane gas (MW = 16)

- 7. The pressure in the annulus (external pressure) at D = 10,000

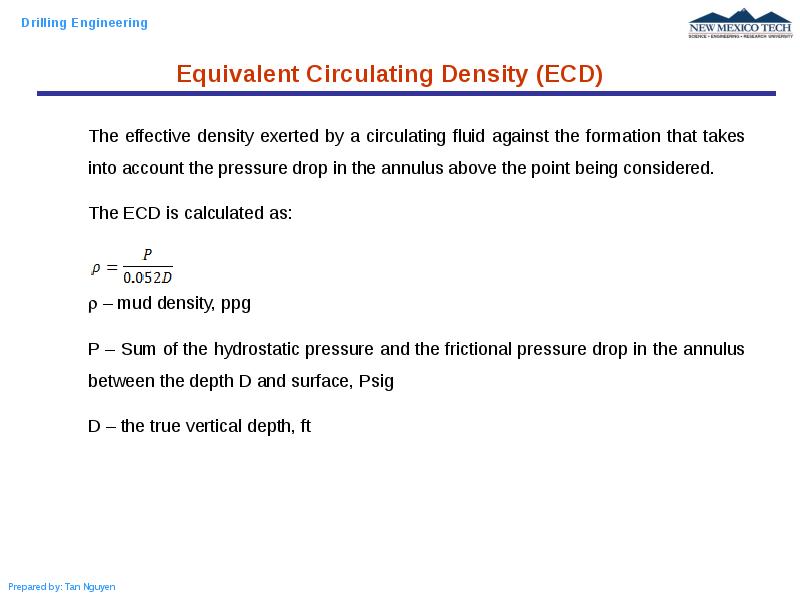

- 10. The effective density exerted by a circulating fluid against the formation

- 11. Example: A 9.5-PPG drilling fluid is circulated through the drill pipe

- 13. 10,000 ft of 19.5-lbm/ft drillpipe and 600 ft of 147 lbm/ft

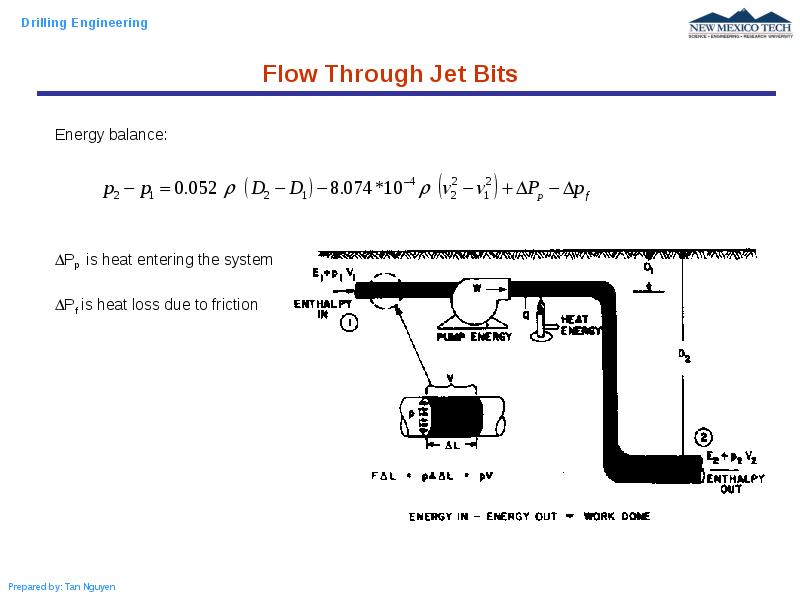

- 14. Energy balance: Pp is heat entering the system Pf is heat

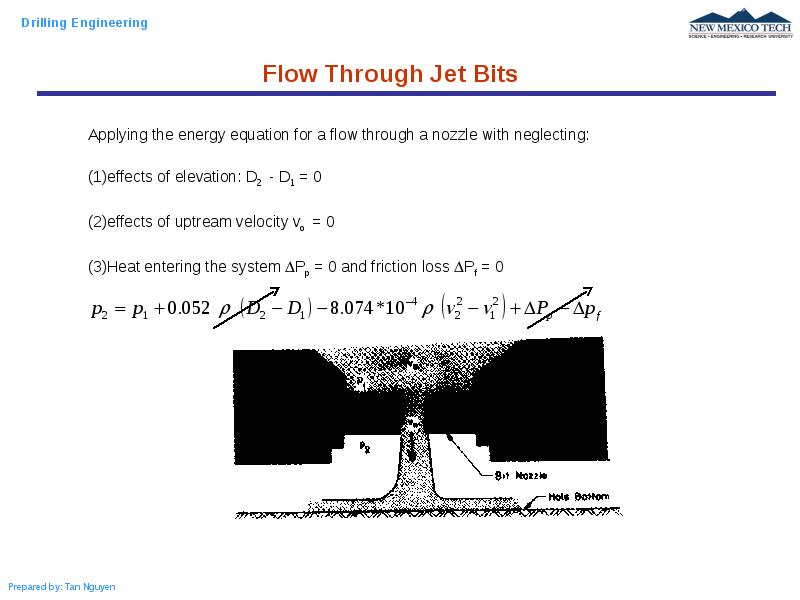

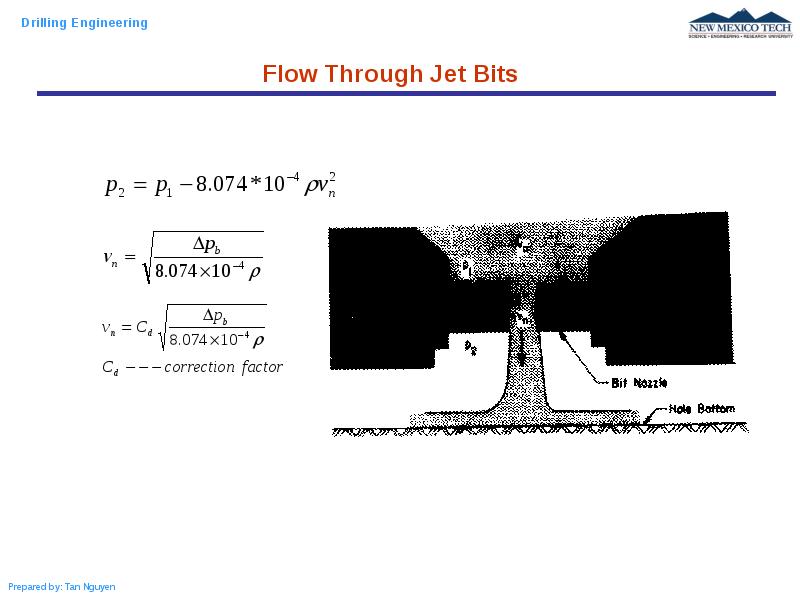

- 15. Applying the energy equation for a flow through a nozzle with

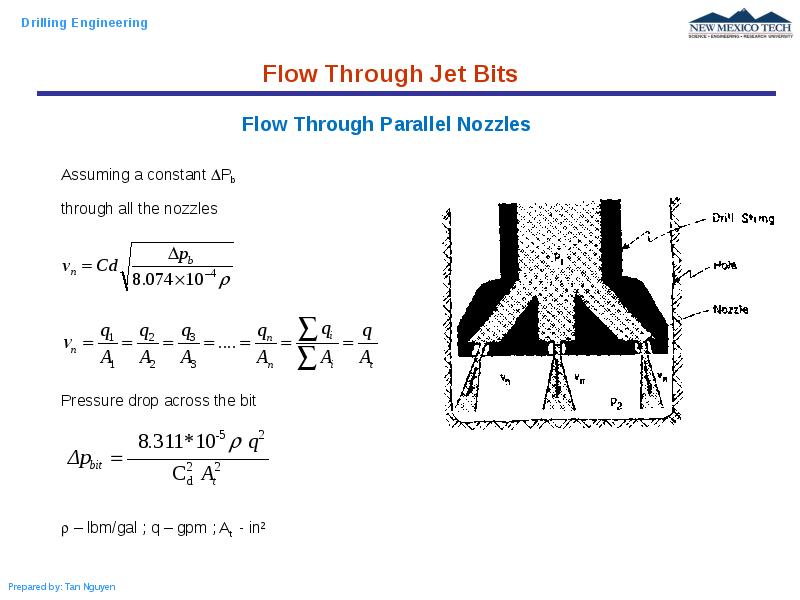

- 17. Assuming a constant Pb through all the nozzles Pressure

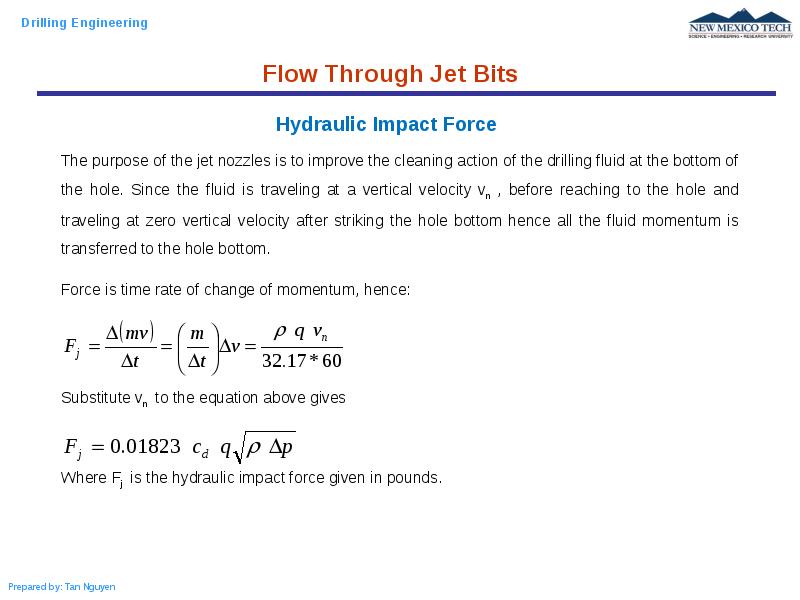

- 18. The purpose of the jet nozzles is to improve the cleaning

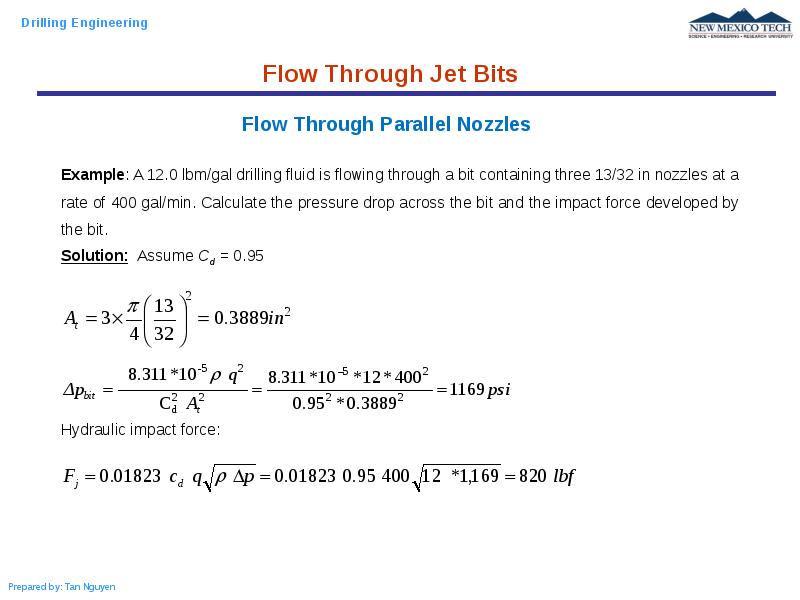

- 19. Example: A 12.0 lbm/gal drilling fluid is flowing through a bit

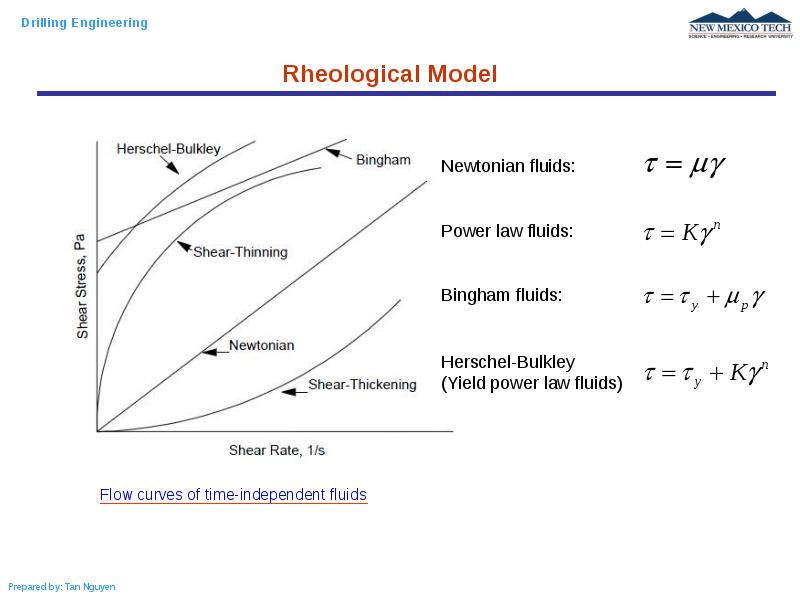

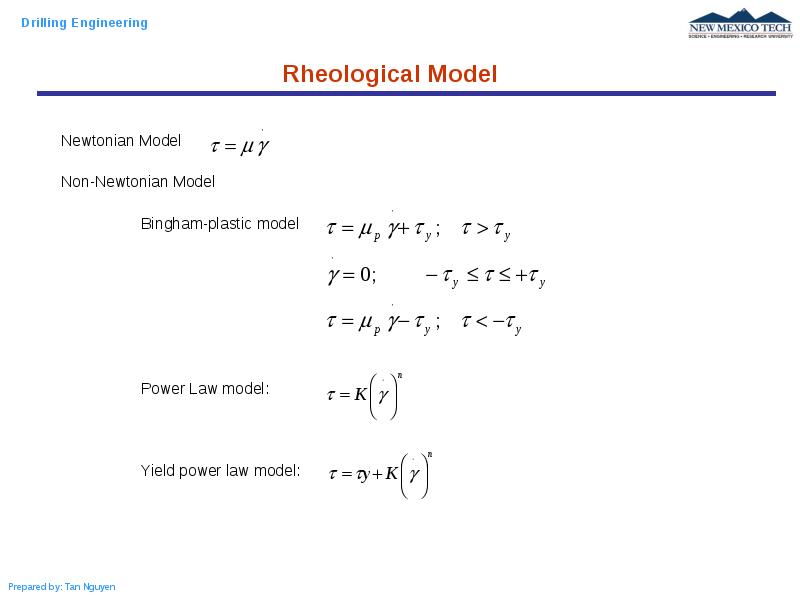

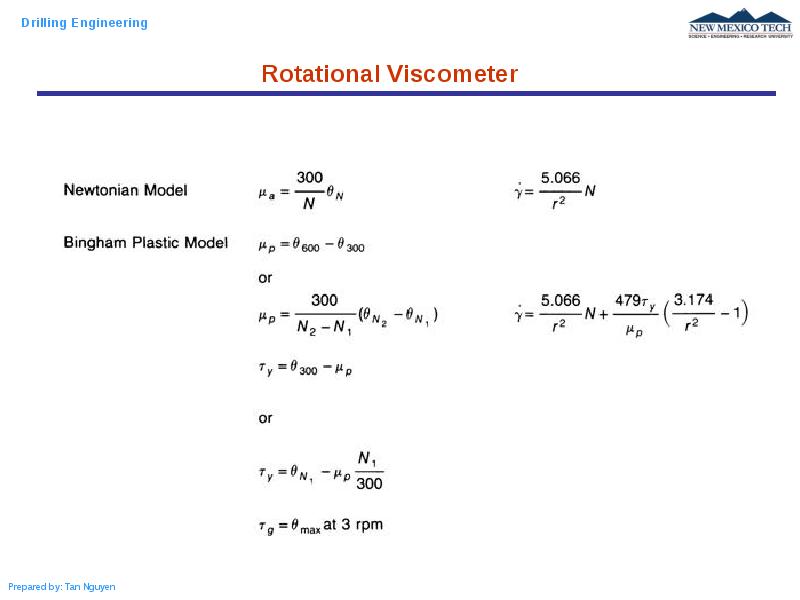

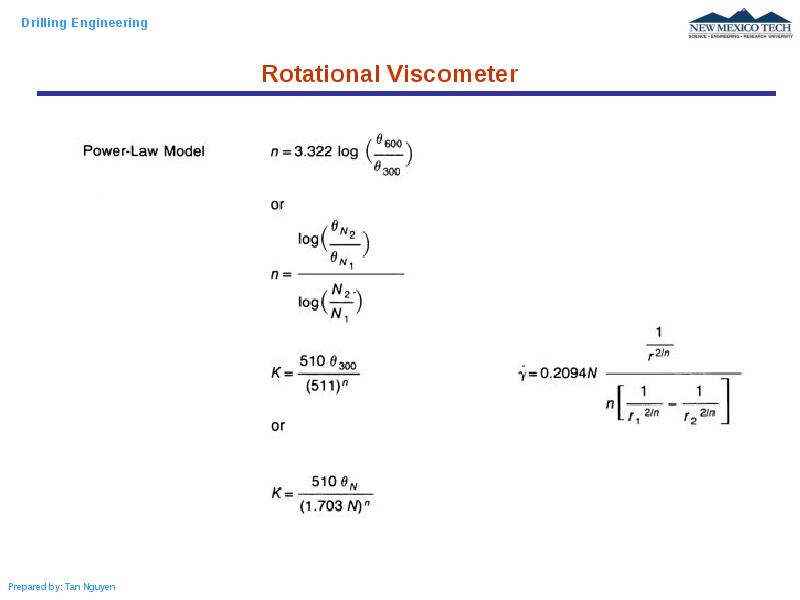

- 21. Newtonian Model Non-Newtonian Model Bingham-plastic model Power Law model: Yield

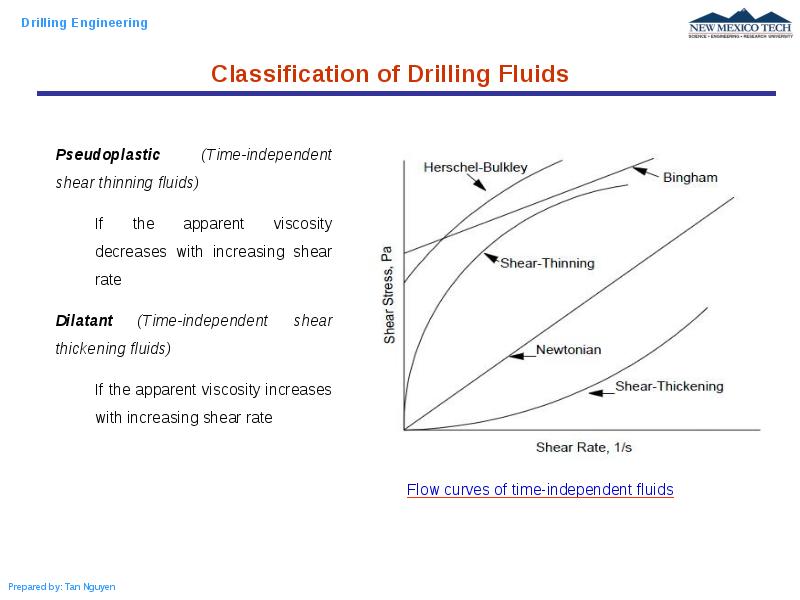

- 22. Pseudoplastic (Time-independent shear thinning fluids) If the apparent viscosity decreases with

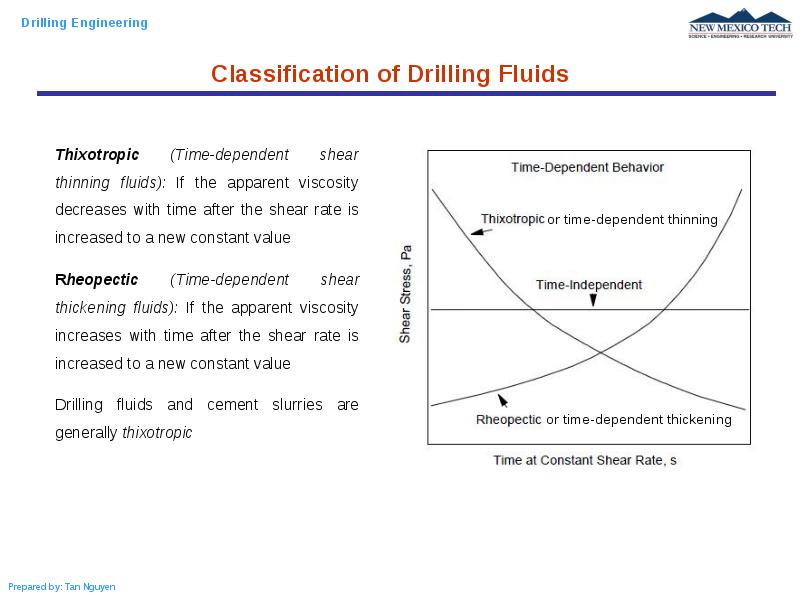

- 23. Thixotropic (Time-dependent shear thinning fluids): If the apparent viscosity decreases with

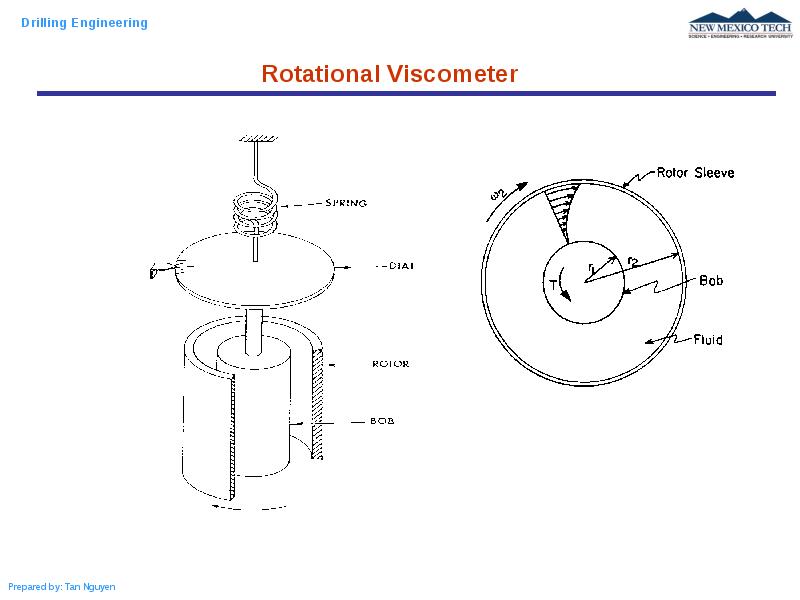

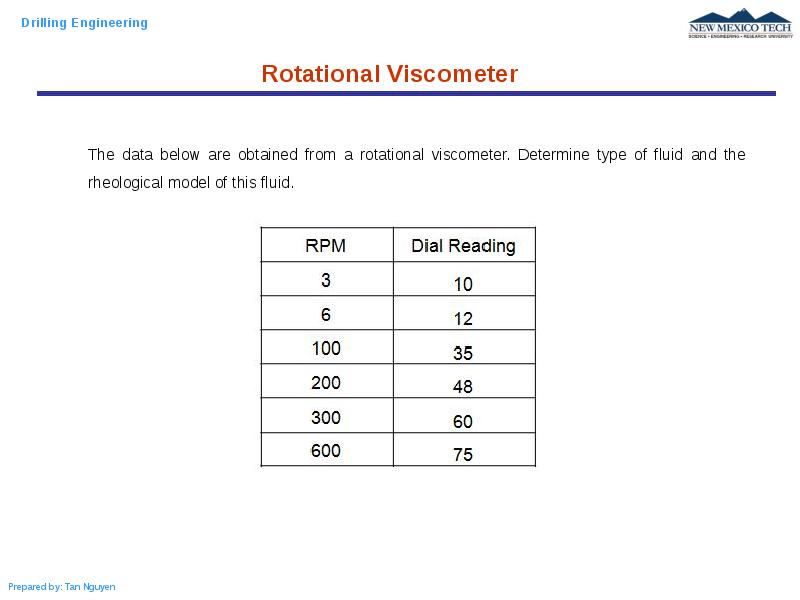

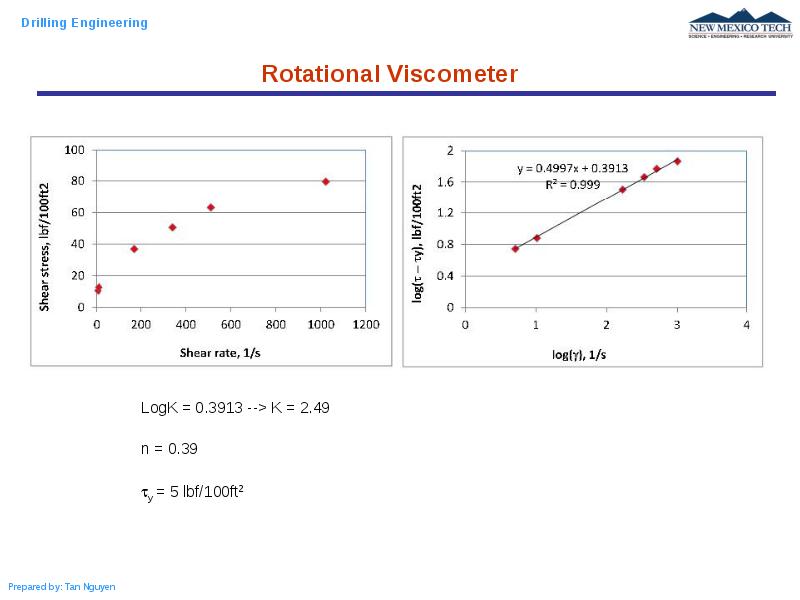

- 25. A rotational viscometer is used to determine type of the fluid

- 30. Скачать презентацию

Слайды и текст этой презентации

Похожие презентации