Internal Сombustion Engine. Fuel Systems. The diesel injection system презентация

Содержание

- 2. Basic Functions of Injection Systems The basic functions of a diesel

- 3. Basic Functions of Injection Systems 3. Fuel metering that precisely meters

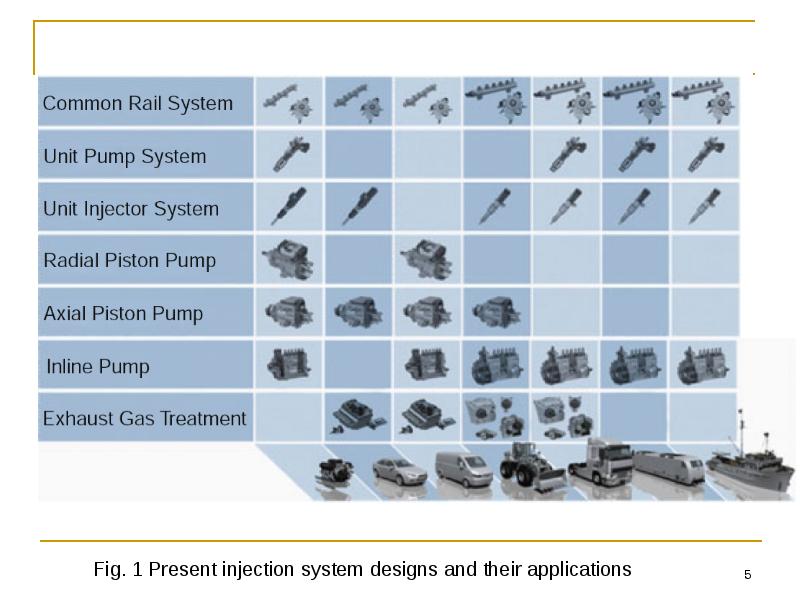

- 4. Types of Injection Systems The basic functions described above are

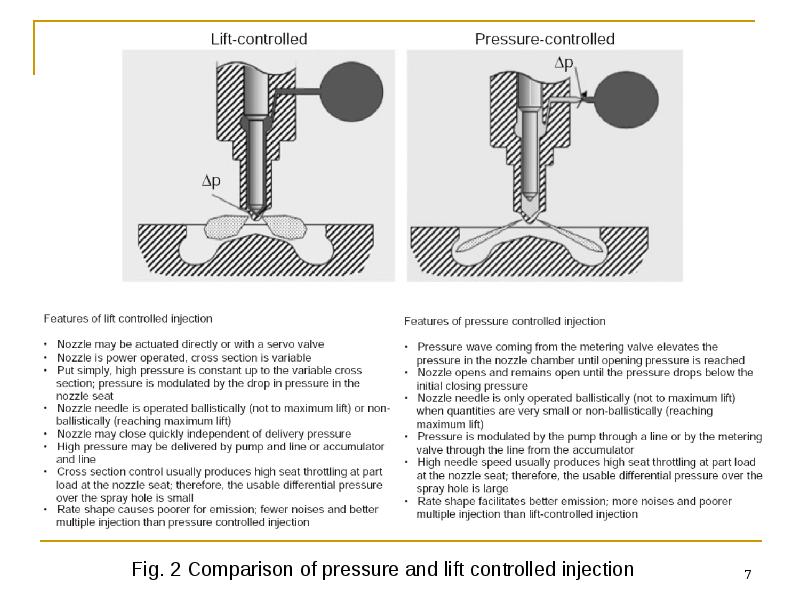

- 6. Types of Injection Systems Accumulator systems on the other hand have

- 8. Types The implementation of common rail systems in virtually every engine

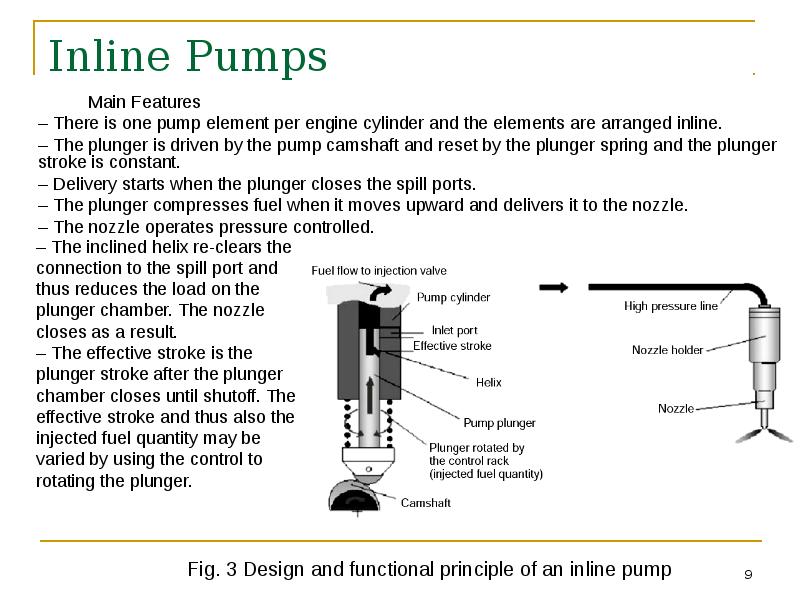

- 9. Inline Pumps Main Features – There is one pump element per

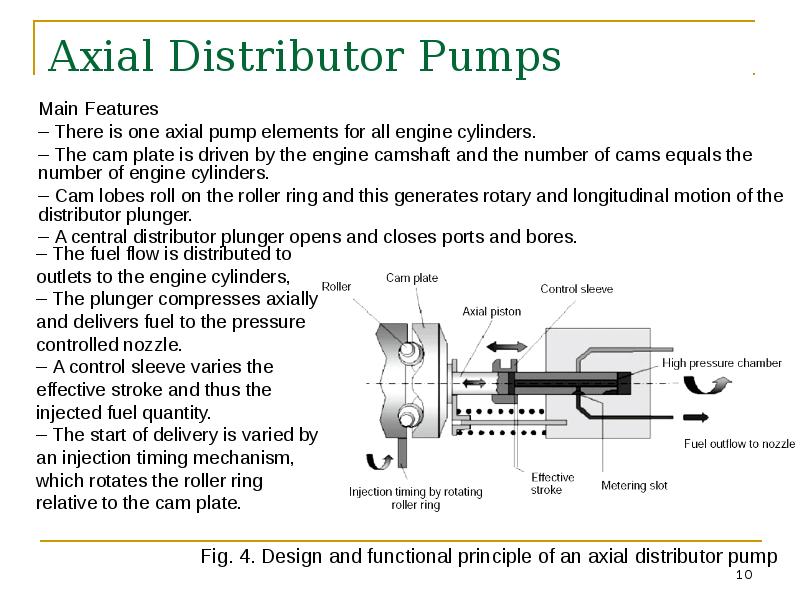

- 10. Axial Distributor Pumps Main Features – There is one axial pump

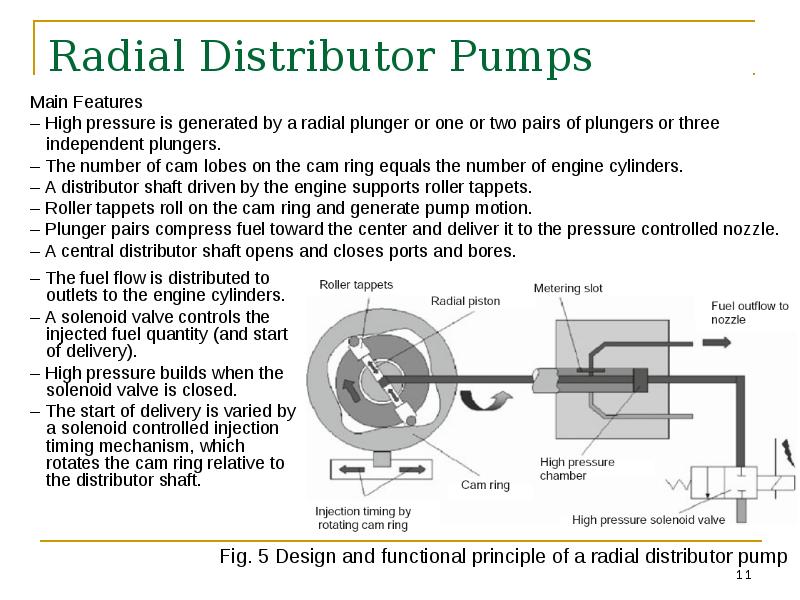

- 11. Radial Distributor Pumps – The fuel flow is distributed to outlets

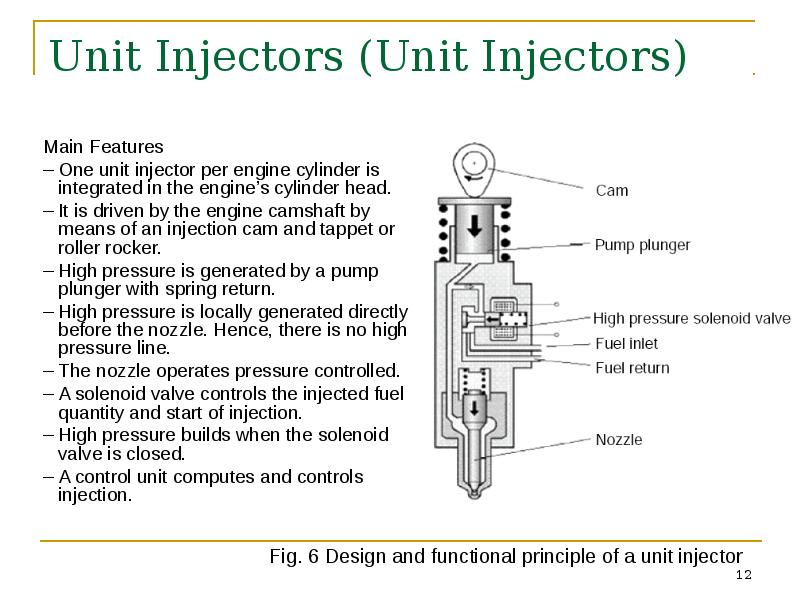

- 12. Unit Injectors (Unit Injectors) Main Features – One unit injector per

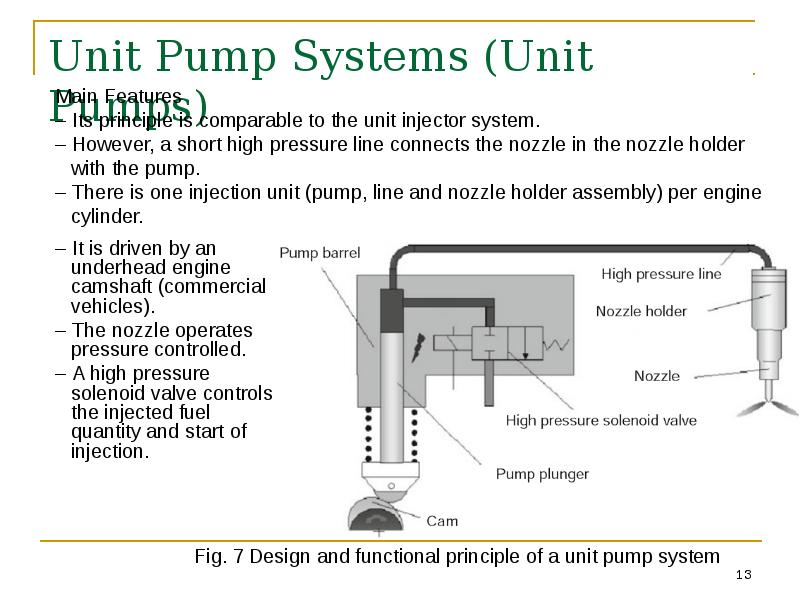

- 13. Unit Pump Systems (Unit Pumps) – It is driven by an

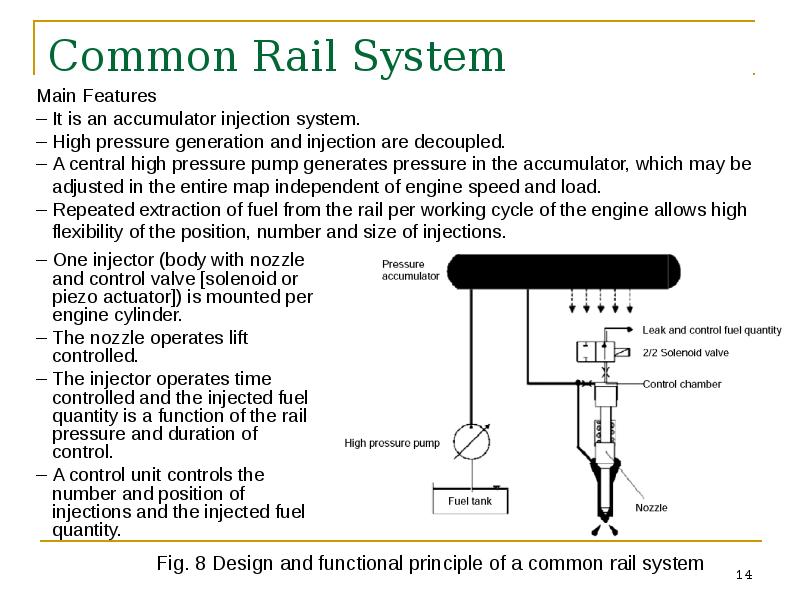

- 14. Common Rail System – One injector (body with nozzle and control

- 15. Common Rail System Design Unlike cam-driven injection systems, the common rail

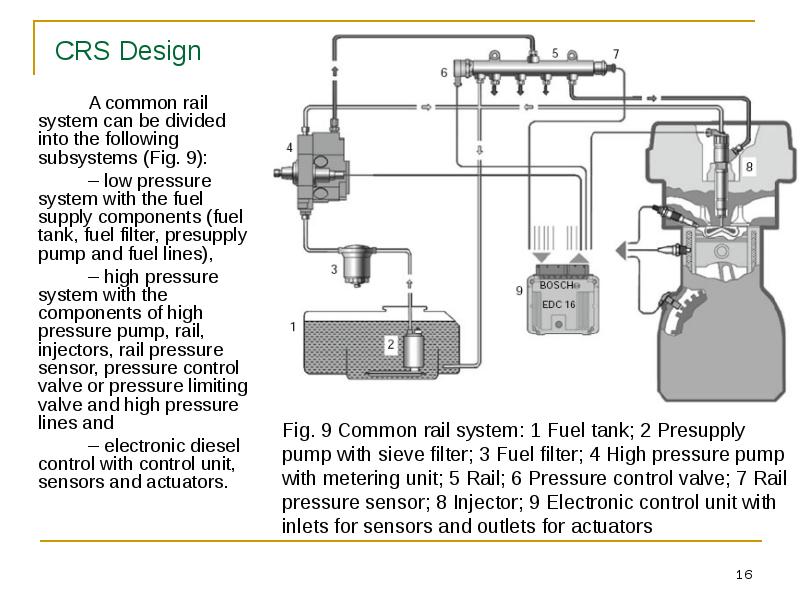

- 16. A common rail system can be divided into the following subsystems

- 17. Common Rail System Design Driven by the engine, the continuously operating

- 18. CR Injectors Common rail injectors with identical basic functions are employed

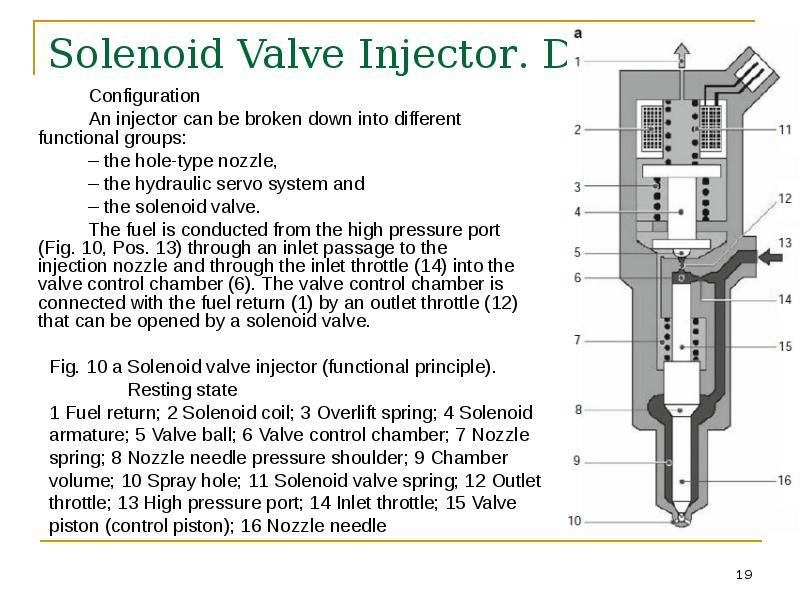

- 19. Solenoid Valve Injector. Design Configuration An injector can be broken down

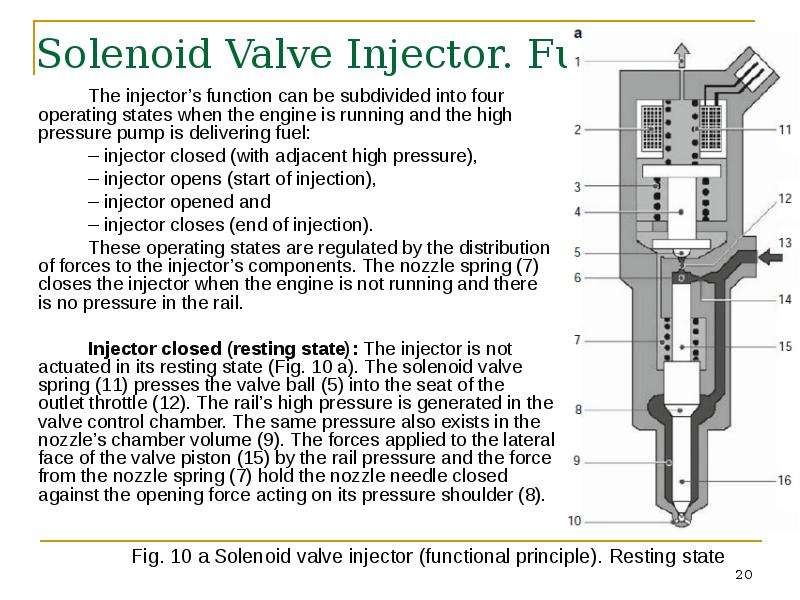

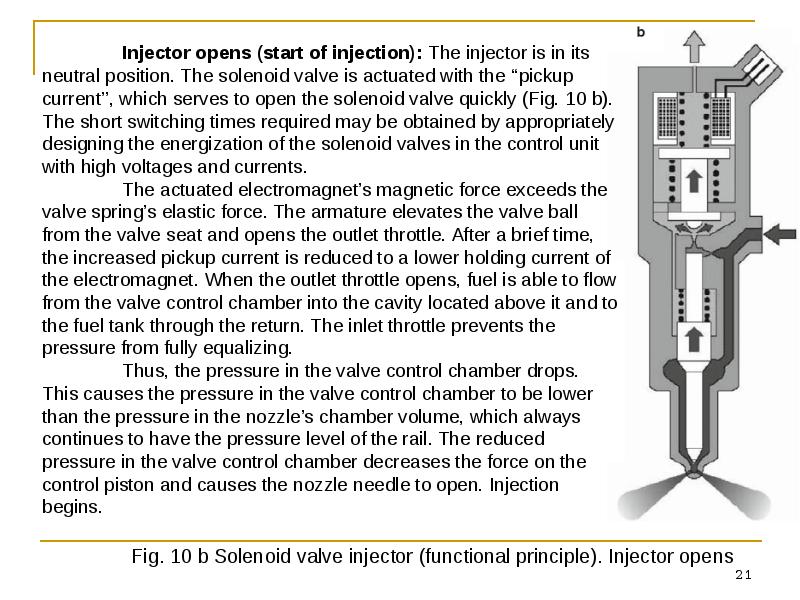

- 20. Solenoid Valve Injector. Function The injector’s function can be subdivided into

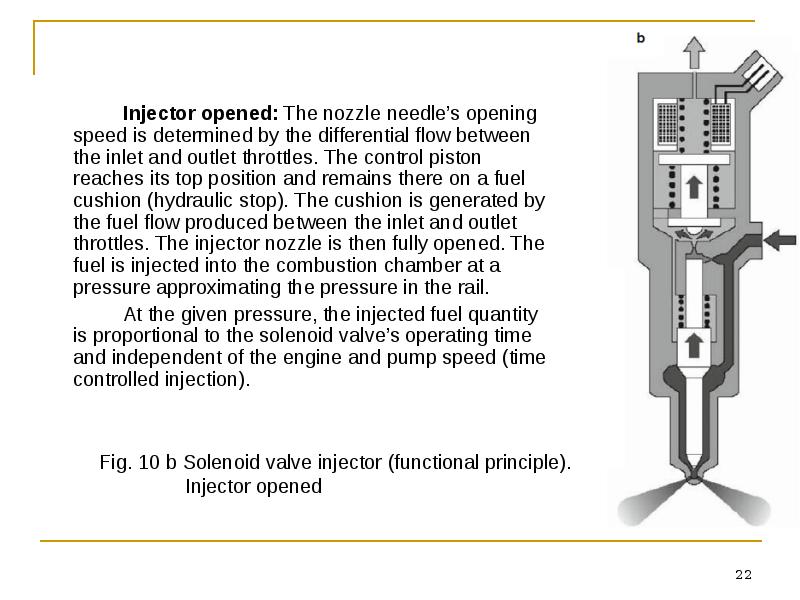

- 22. Injector opened: The nozzle needle’s opening speed is determined by the

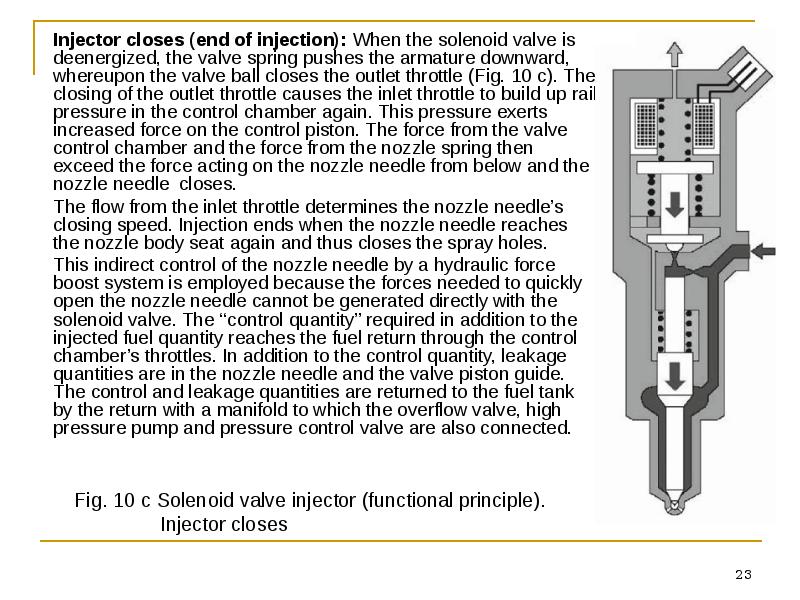

- 23. Injector closes (end of injection): When the solenoid valve is deenergized,

- 24. Скачать презентацию

Слайды и текст этой презентации

Скачать презентацию на тему Internal Сombustion Engine. Fuel Systems. The diesel injection system можно ниже:

Похожие презентации