Reliability of bearing knots презентация

Содержание

- 2. FUNCTION OF A BEARING The main function of a rotating shaft

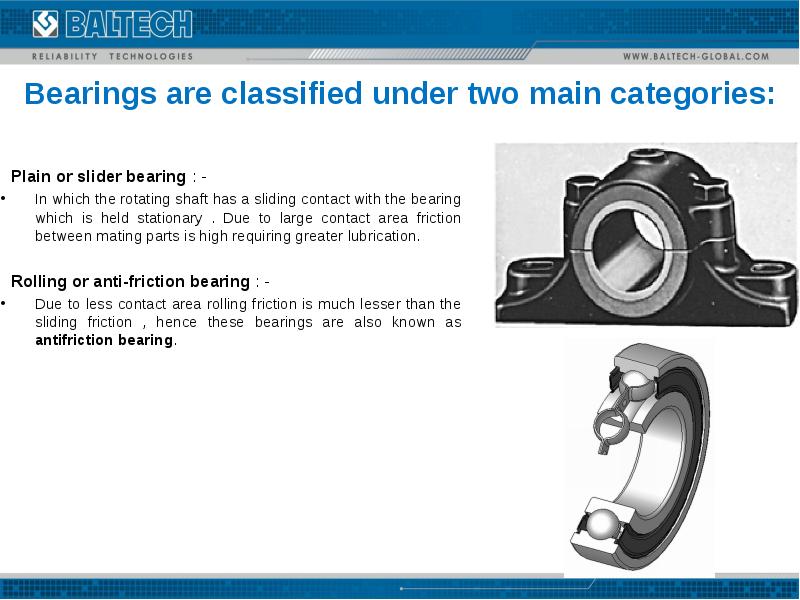

- 3. Bearings are classified under two main categories: Plain or slider bearing

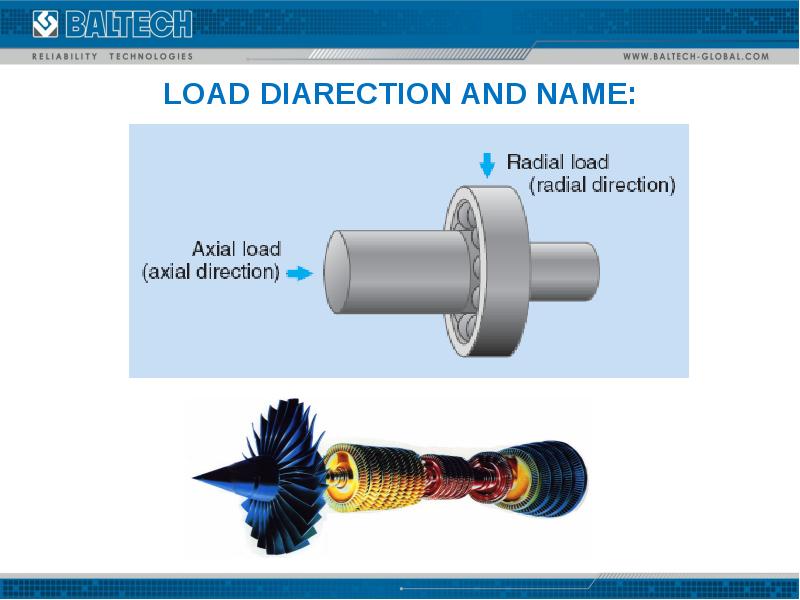

- 4. LOAD DIARECTION AND NAME:

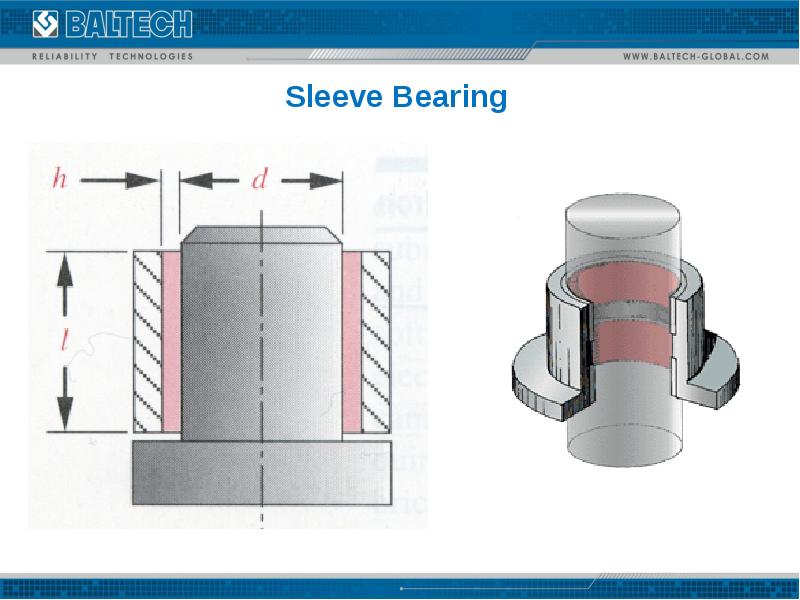

- 5. Sleeve Bearing

- 6. Description: Bearing used to constrain, guide, or reduce friction in rotary

- 7. Sleeve Bearing Materials Relative softness (to absorb foreign particles), reasonable strength,

- 8. Materials Whitemetal - usually used as a lining bonded to bronze,

- 9. Materials Sintered bronze - Sintered bronze is a porous material which

- 10. Types of Lubrication Hydrostatic Hydrodynamic Boundary Lubrication Dry Bearings

- 11. Advantages and disadvantages of the plain bearing Plain bearing are cheap

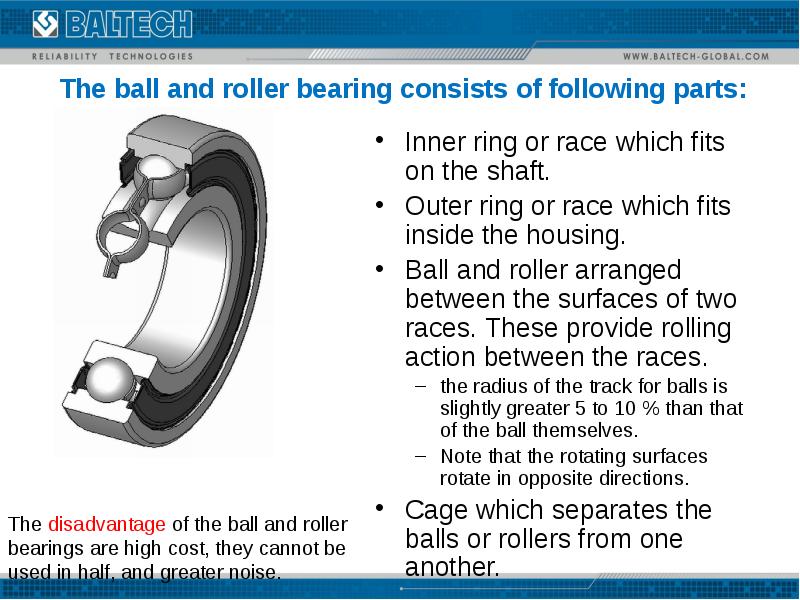

- 12. Ball and roller bearings due to low rolling friction these

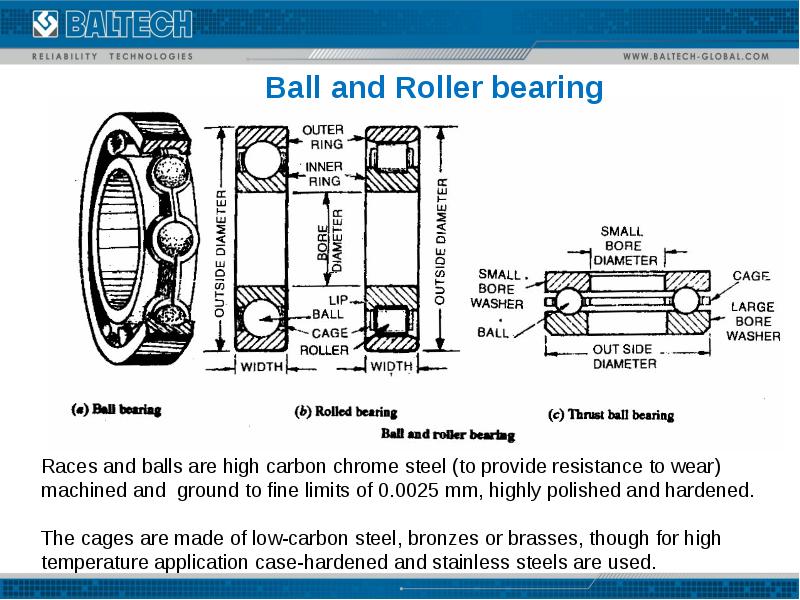

- 13. Ball and Roller bearing

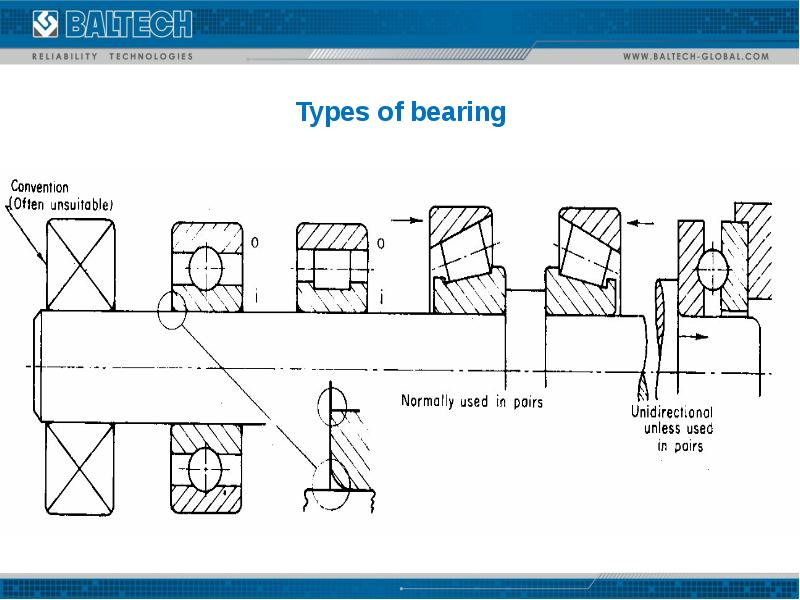

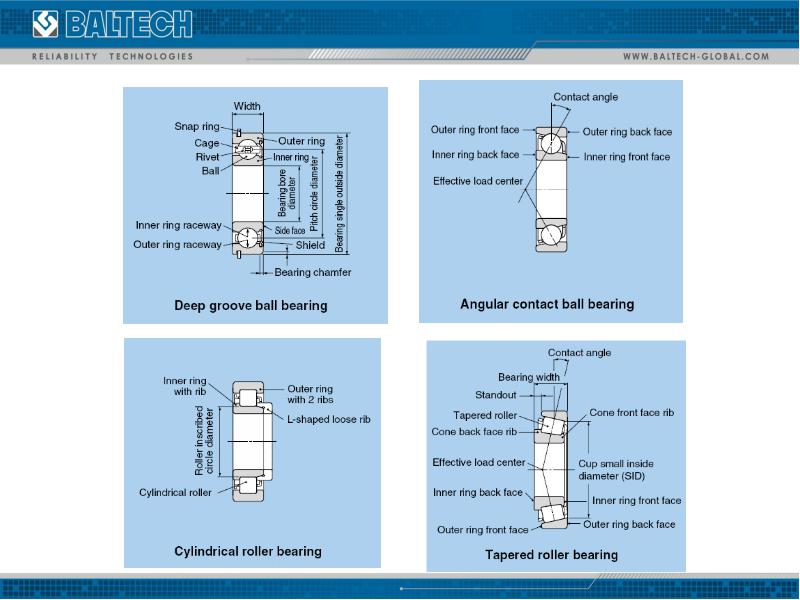

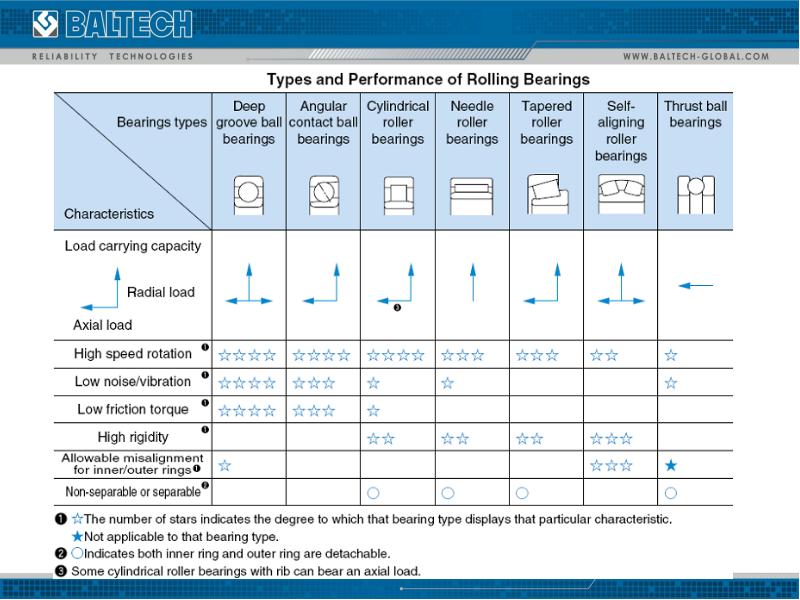

- 15. Types of bearing

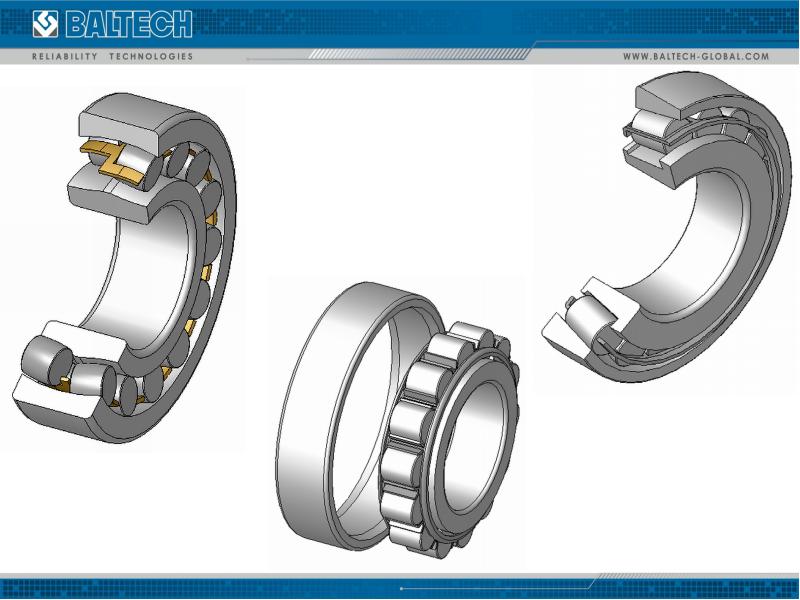

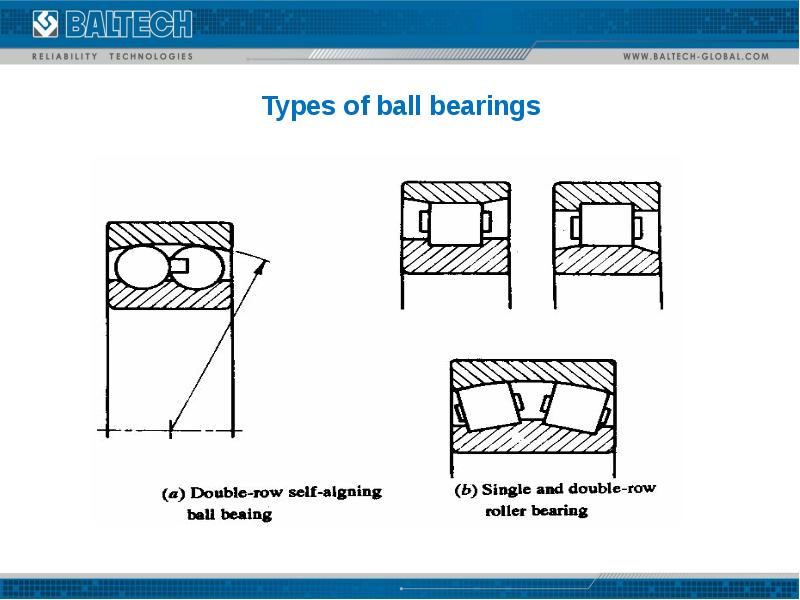

- 17. Types of ball bearings

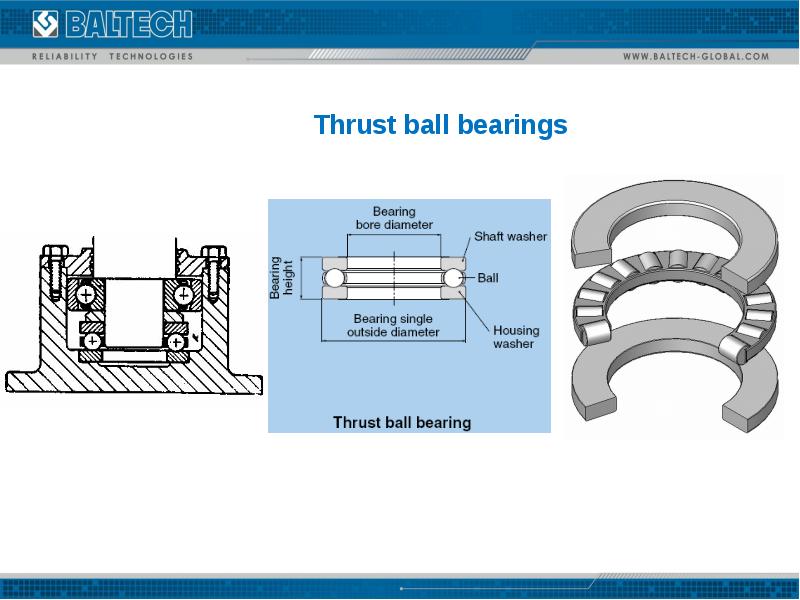

- 20. Thrust ball bearings

- 22. Tapered roller bearing (TRB): Tapered roller bearing (TRB): TRB can take

- 23. Needle ball bearing

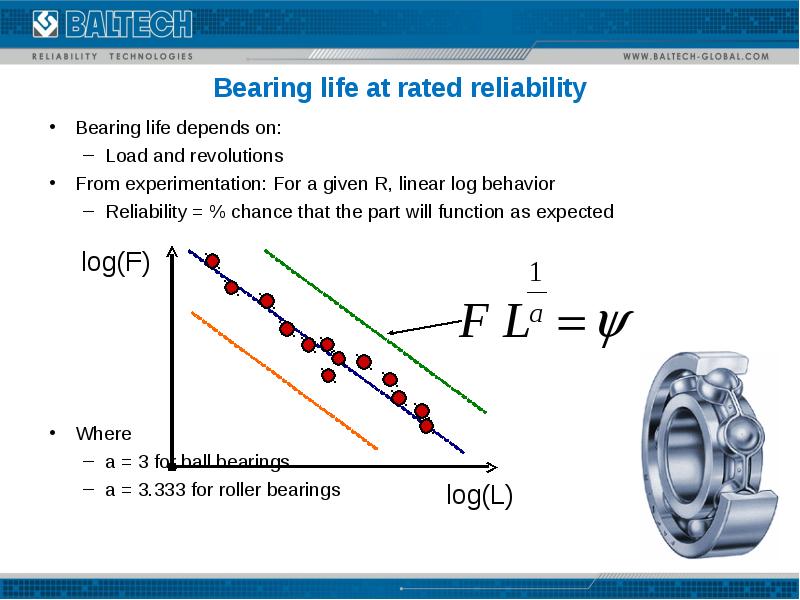

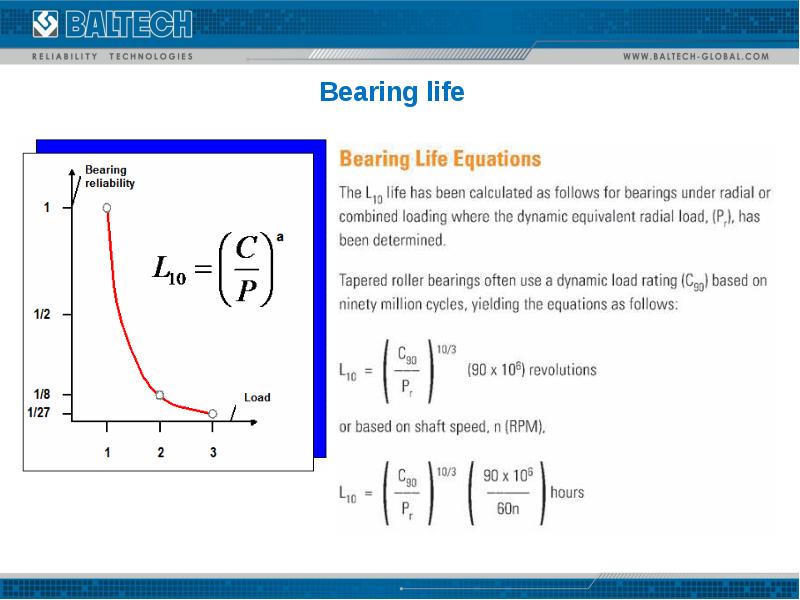

- 34. Bearing life at rated reliability Bearing life depends on: Load and

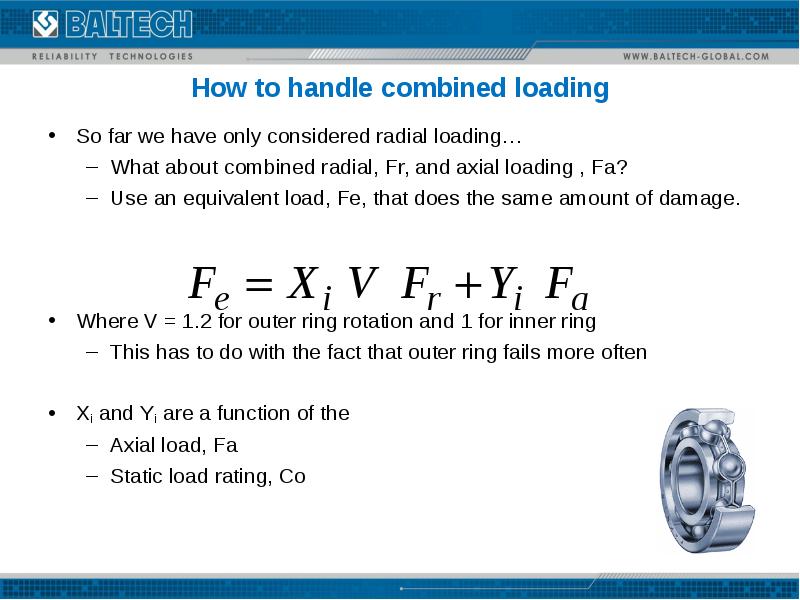

- 35. How to handle combined loading So far we have only considered

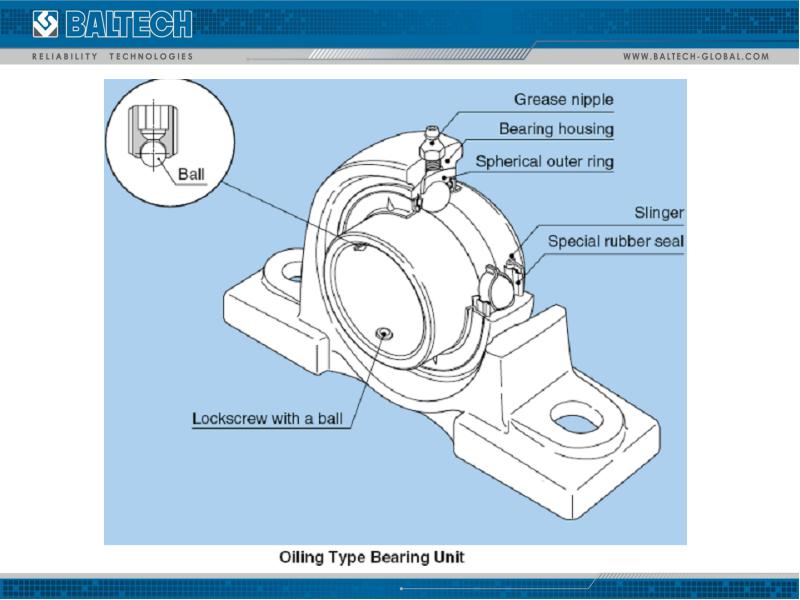

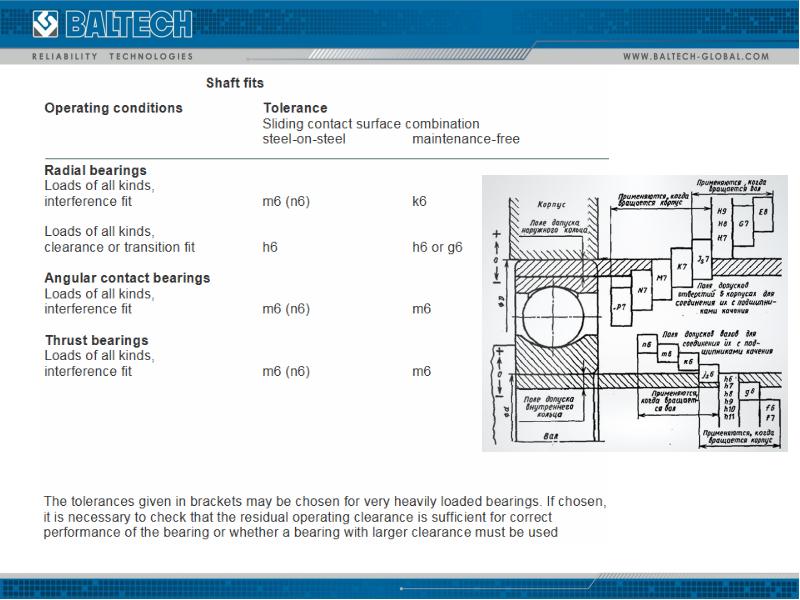

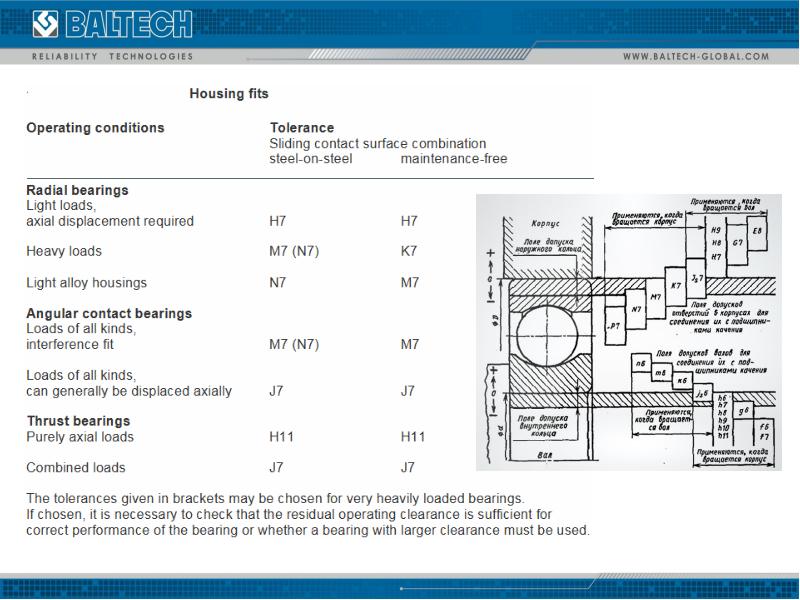

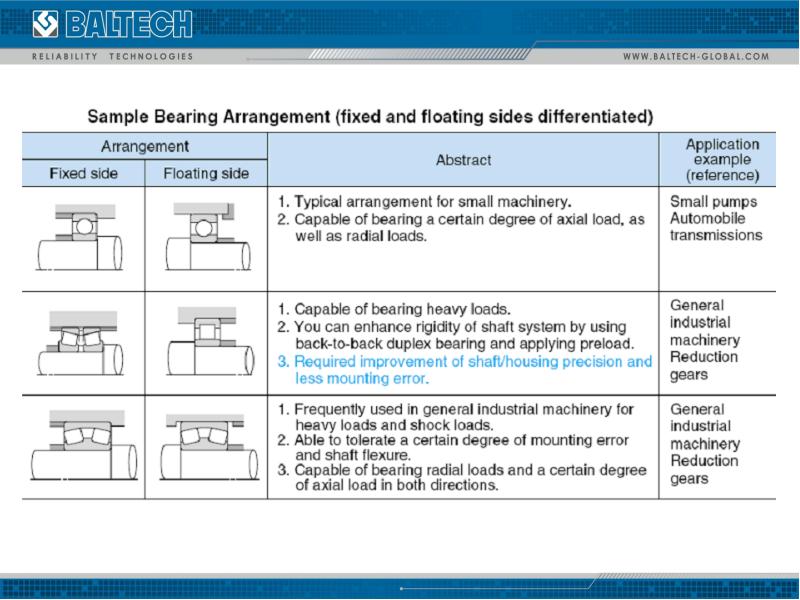

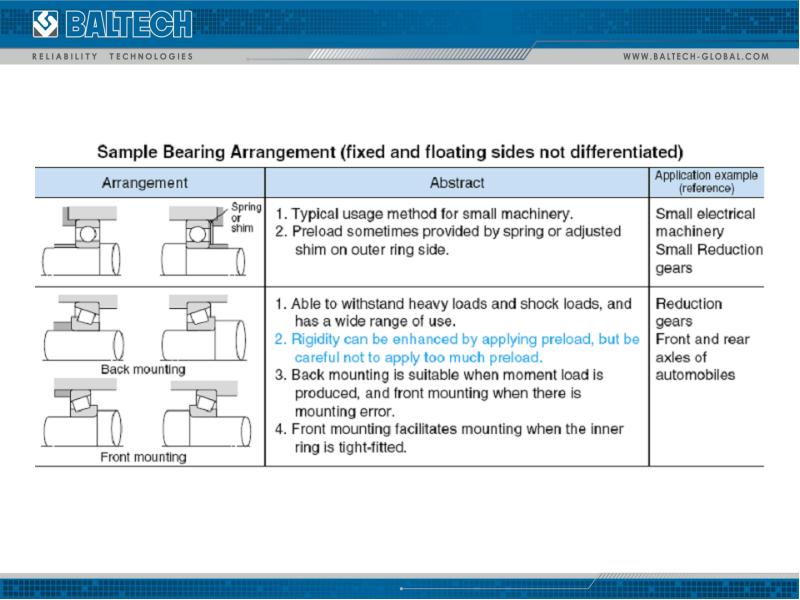

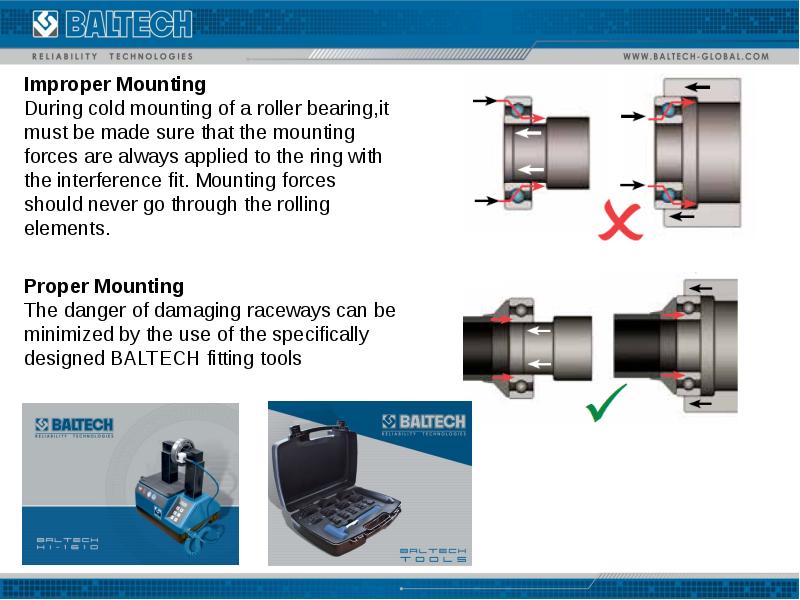

- 37. Bearing Mounting For instrument bearings, certain special considerations should be

- 49. Скачать презентацию

Слайды и текст этой презентации

Похожие презентации