ESD Class 0 Protection Stress Levels презентация

Содержание

- 2. ESD Event Classification From EMI to EOS - Speed Classification EMI

- 3. Introduction 1What is an ESD Sensitivity Level? 2How is it

- 4. Overview ESD Models Provide a way to characterize the sensitivity

- 5. Purpose of ESD Models Models establish Benchmarks for ESD Sensitivity.

- 6. ESD Event Test Models Human Body (HBM): discharging event through the

- 7. ESD Damage to Die Structure Damage types can vary depending on

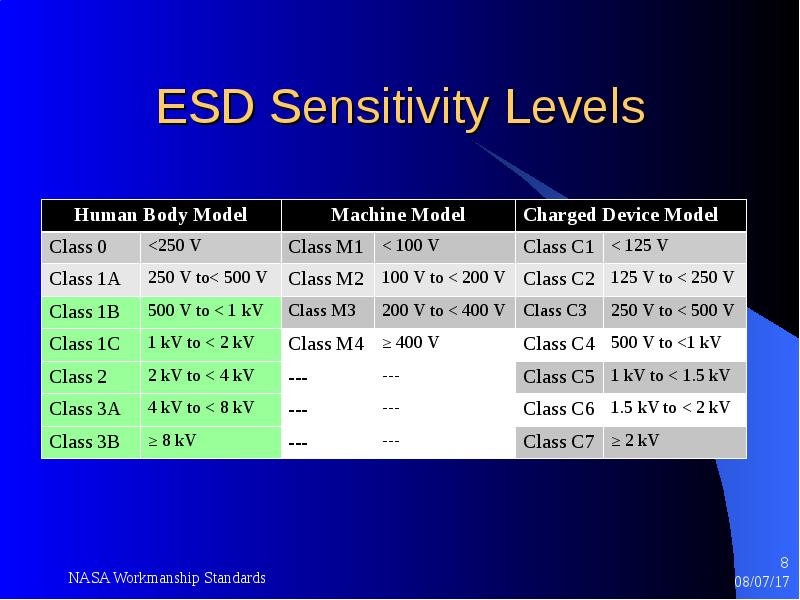

- 8. ESD Sensitivity Levels

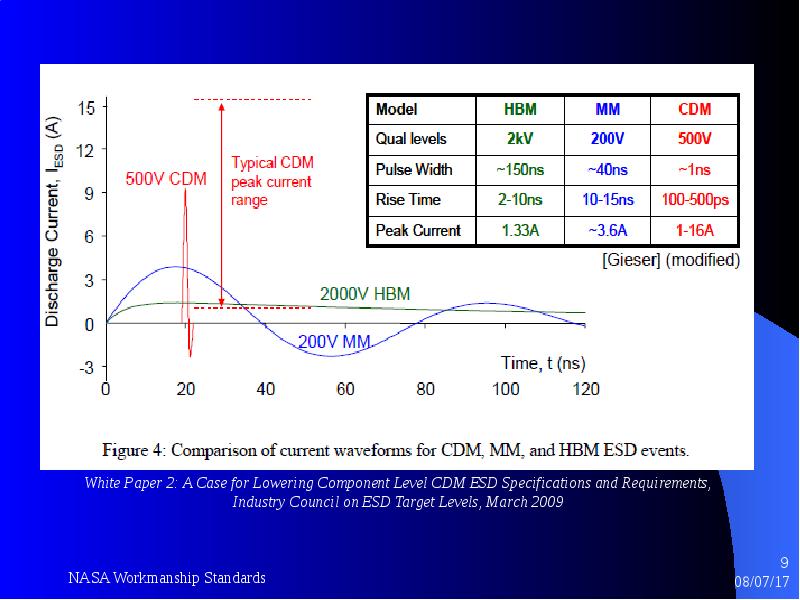

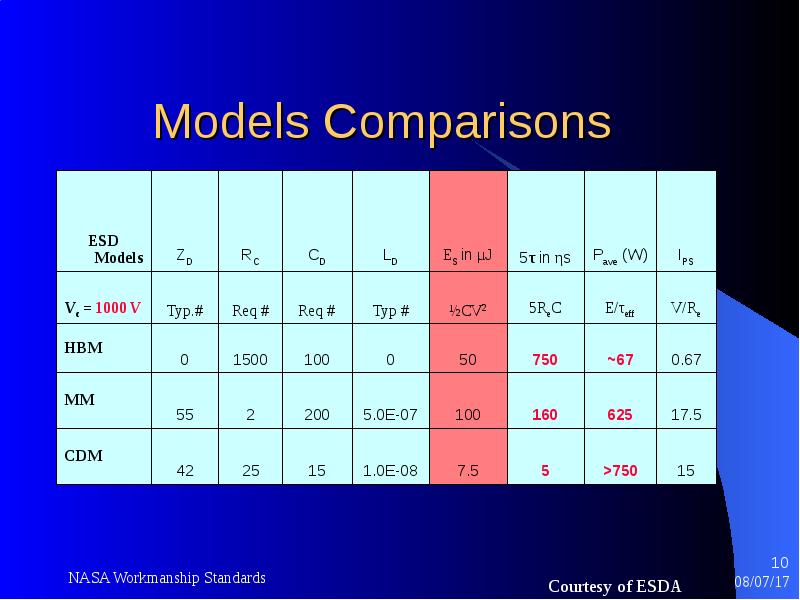

- 10. Models Comparisons

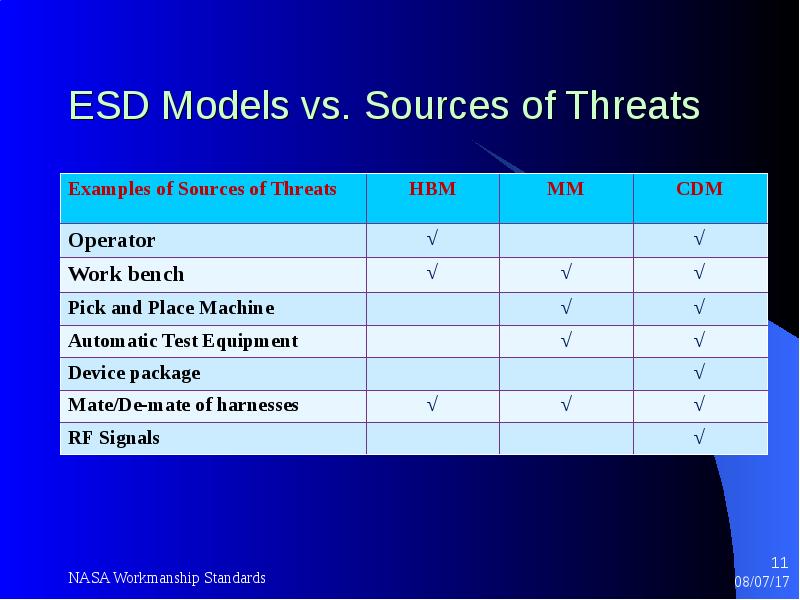

- 11. ESD Models vs. Sources of Threats

- 12. “Class 0” Parts Protection “Class 0” has become the generic term

- 13. Model Implementation NASA-HDBK-8739.21 (in Approval Cycle) Guide for Creating an ANSI/ESD

- 14. Model Implementation Recent failures of high speed devices (LVDS, FPGAs) drive

- 15. Class 0 & CDM Class 0 refers to the HBM model

- 16. Limits of Design-in Protection CDM protection by the design is driven

- 17. Protection of Devices Sensitive to Class 0 ESD “Shalls” related to

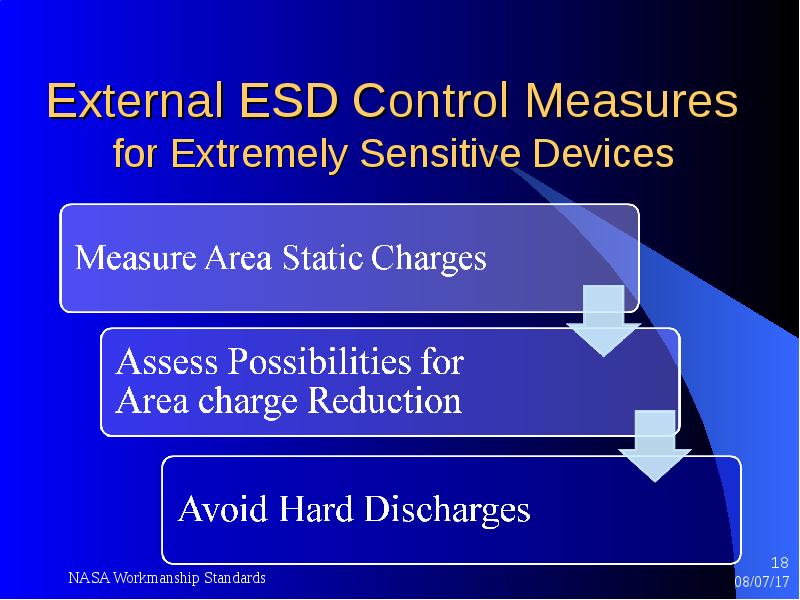

- 18. External ESD Control Measures for Extremely Sensitive Devices

- 19. Charged Board Events CBE are caused when a board is pulled

- 20. Where to Get More Information WEB searches under “ESD Models” ESDA

- 21. References ANSI/ESD STM5.1-2001 ESD Sensitivity Testing (HBM) ANSI/ESD STM5.2-1999 ESD Sensitivity

- 22. Thank you Any Questions?

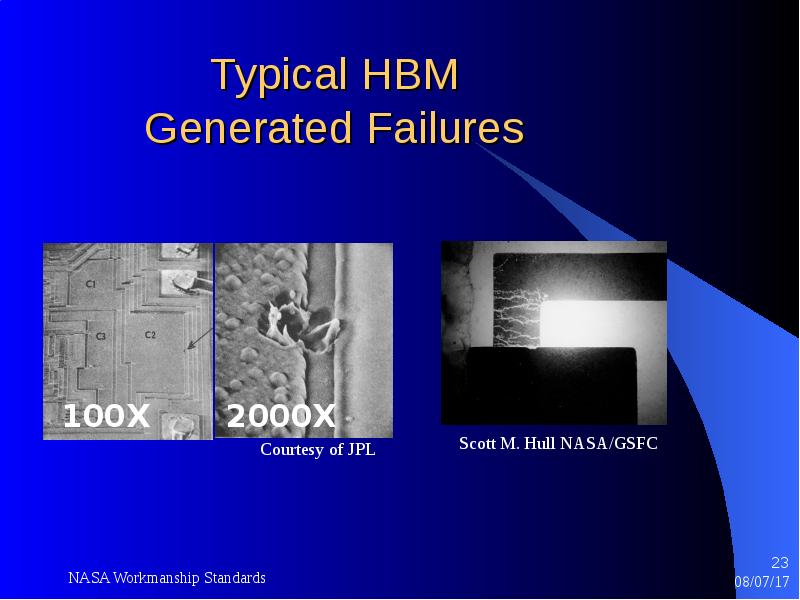

- 23. Typical HBM Generated Failures

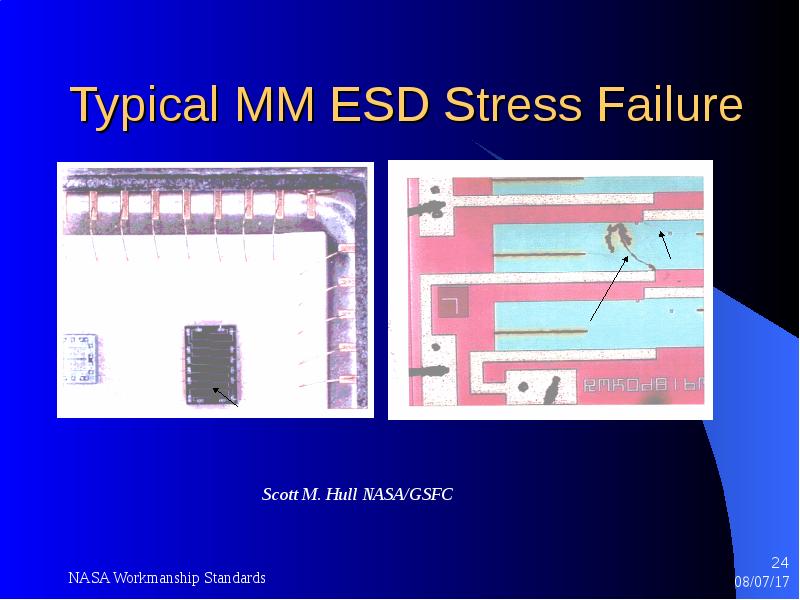

- 24. Typical MM ESD Stress Failure

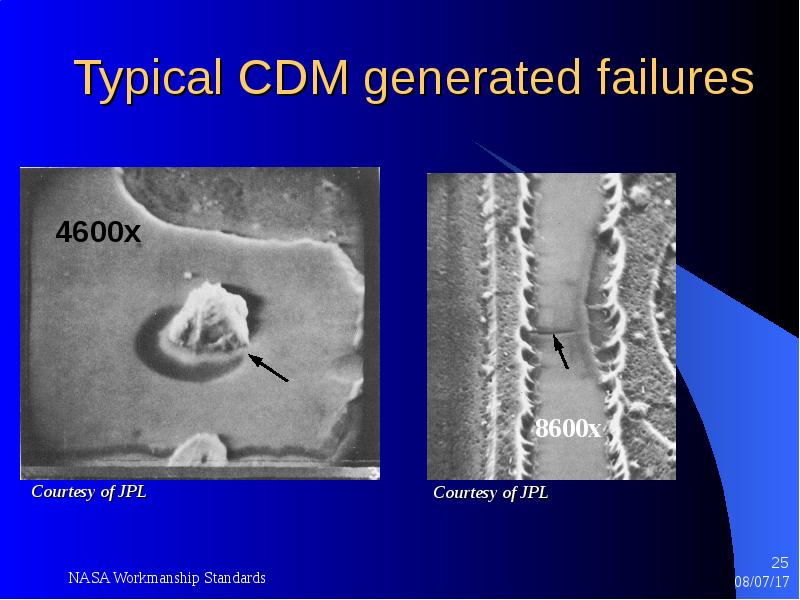

- 25. Typical CDM generated failures

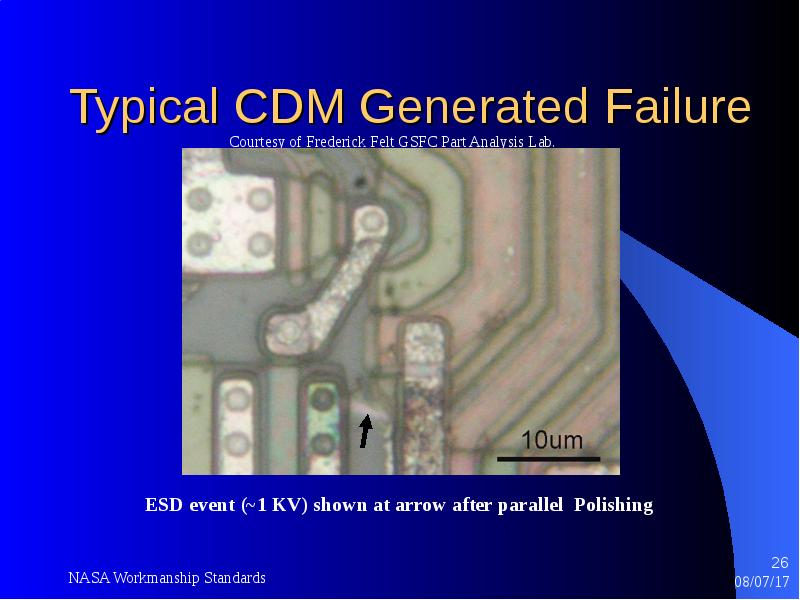

- 26. Typical CDM Generated Failure

- 27. Скачать презентацию

Слайды и текст этой презентации

Скачать презентацию на тему ESD Class 0 Protection Stress Levels можно ниже:

Похожие презентации