Refrigerant systems and their energy performance презентация

Содержание

- 2. What is efficiency What is efficiency Efficiency is the relation between

- 3. Definition of efficiency COP Definition of efficiency COP In the HVAC

- 4. Conversion factor US units Conversion factor US units conversion

- 5. Definition of efficiency - EER Definition of efficiency - EER In

- 6. Measuring of efficiency - EER Measuring of efficiency - EER The

- 7. Part Load Efficiency ESEER Part Load Efficiency ESEER EER is only

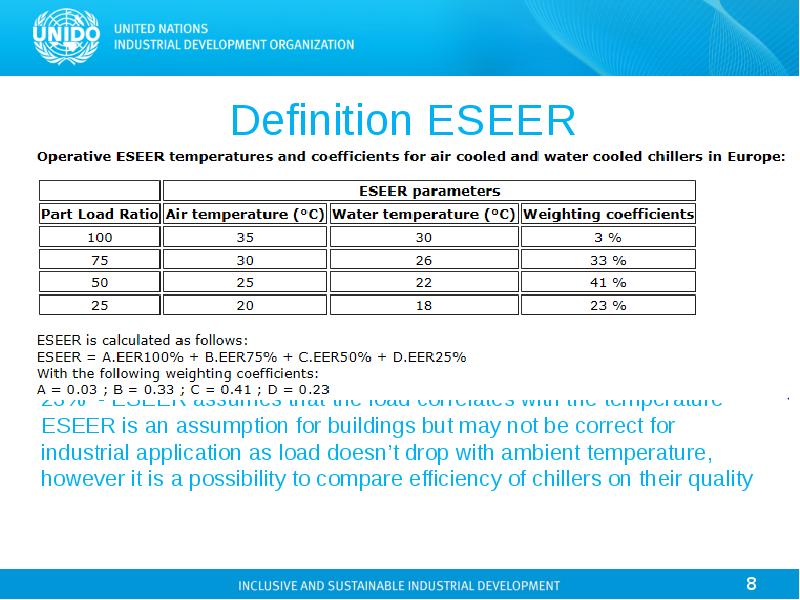

- 8. Definition ESEER Definition ESEER ESEER is basically the summarizing of the

- 9. Definition IPLV Definition IPLV The IPLV stands for Integrated Part Load

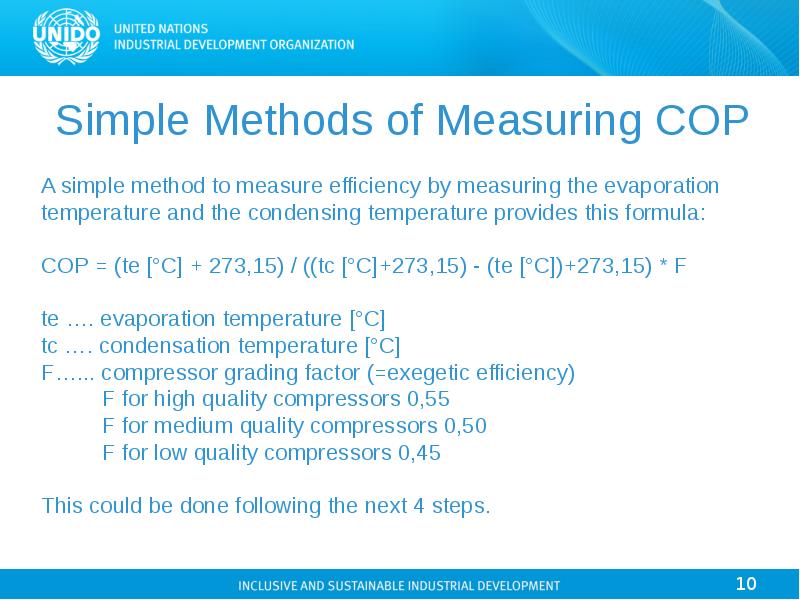

- 10. Simple Methods of Measuring COP Simple Methods of Measuring COP A

- 11. Measuring Pressure on Low and High Side Measuring Pressure on Low

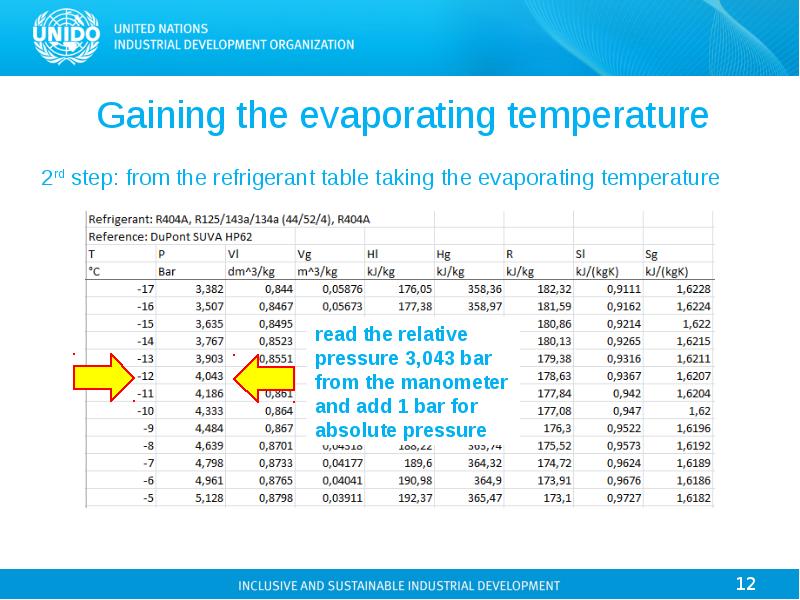

- 12. Gaining the evaporating temperature Gaining the evaporating temperature 2rd step: from

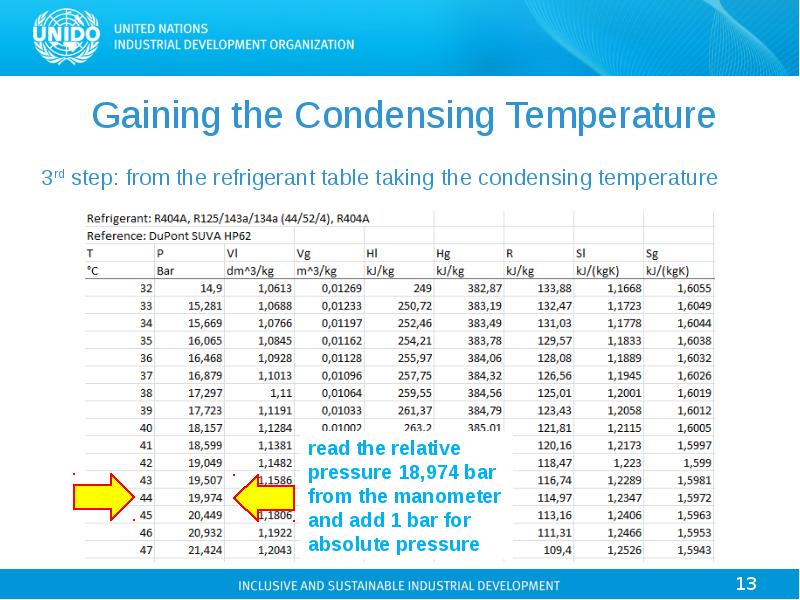

- 13. Gaining the Condensing Temperature Gaining the Condensing Temperature 3rd step: from

- 14. Calculation of COP Calculation of COP 4th step: calculation of COP

- 15. Measuring and monitoring entire systems Measuring and monitoring entire systems On

- 16. Monitoring Devices Monitoring Devices Usually most of the devices are electricity

- 17. International Systematical Energy Management Standard International Systematical Energy Management Standard ISO

- 18. What influences the efficiency of refrigeration systems What influences the

- 19. What influence has the evaporator What influence has the evaporator

- 20. What influence has the condenser What influence has the condenser

- 21. What influence has pressure drop What influence has pressure drop

- 22. What influence has variable flow What influence has variable flow

- 23. What influence has maintenance What influence has maintenance And

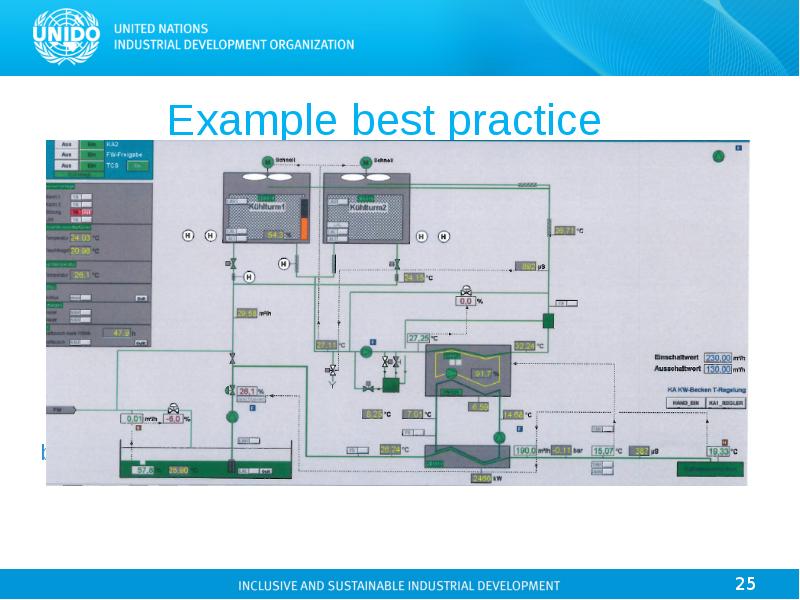

- 24. Example best practice Example best practice An industrial plant

- 25. Example best practice Example best practice before design change

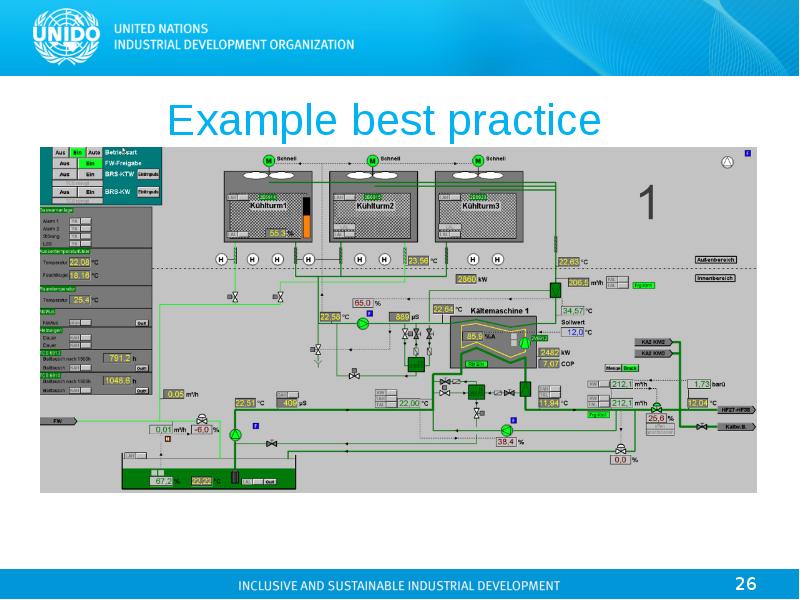

- 26. Example best practice Example best practice After design change

- 27. Example best practice Example best practice After modification of:

- 28. Some benchmark of good COP Some benchmark of good COP The

- 29. Some benchmark of good COPs Some benchmark of good COPs Here

- 30. Thank you for your attention Thank you for your attention

- 31. Скачать презентацию

Слайды и текст этой презентации

Скачать презентацию на тему Refrigerant systems and their energy performance можно ниже:

Похожие презентации